From Standard to Non-Standard: The Challenges Behind Customization

2026.01.30In the world of dies, challenges are part of everyday work.

Everyone knows that for a product to stand out and be favored by customers in the market, it must highlight its differentiation—giving customers a clear reason to choose it. When selecting a product, customers are not only looking for something that meets basic requirements; more often, they are seeking a solution —whether to optimize existing quality or to resolve current problems.

For manufacturers, standardized products are the most economically efficient to produce. However, in the face of rapidly changing environments and evolving industries, an increasing number of customers are now demanding customized solutions rather than standard products.

However, what we call “customization” does not necessarily mean delivering a completely different product. More often, it is about solving the customer’s specific problem.

For example, when a customer uses a special formulation, excessive internal pressure may build up inside the die during production, causing excessive die-lip deformation and resulting in an unstable production line. Through simulation analysis and adjustments to the internal channel design, the line can return to stable operation once the new die is installed.

This type of design is not something novel or unconventional. Rather, it is the result of the team’s extensive experience and professional judgment, enabling us to quickly identify and deliver a solution that truly meets the customer’s needs.

Read More:The base of innovation-customized service

There is also another type of customer who faces uncertainty in both new materials and process control, a situation that often arises during new product development. Before moving into mass production, multiple rounds of testing and adjustment are required. In such cases, extrusion or coating dies and equipment designed specifically for testing become the most effective tools to support customers throughout the R&D process.

The key difference between dies used on pilot or laboratory lines and those used on standard production lines lies in their purpose. Experimental dies are required to handle a wider range of materials and processing conditions. As a result, their design must take many more factors into account—capable of simulating real production conditions while also providing reliable and meaningful data, and even enabling sample production.

Only by integrating experience from design, machining, and process development, and translating that know-how into practical solutions, can such customized technical support be delivered to customers.

In the world of dies, the challenges of customization are always part of everyday work.

The essence of customization lies in problem-solving, and the real challenge is comprehensive capability.

Today, customization has long moved beyond the boundaries of standard specifications. More often, it means delivering practical solutions. Being able to propose solutions that are both concrete and feasible is a true test of a manufacturer’s overall strength. This includes:

Design capability:

Simulation tools are accessible to everyone, but how those tools are applied—together with sufficient experience—to truly optimize a design is what makes the difference. That is where experience matters. Creating the first die requires action and courage; progressing from the first die to the ten-thousandth die involves accumulated know-how—such as choosing between fishtail, coat-hanger, or T-type flow channels, and determining the appropriate feeding mechanisms.

This is the result of extensive expertise and experience coming together. Tools themselves are easy to use; how effectively they are applied is what sets professionals apart.

Applying simulation tools effectively in design requires the accumulation and refinement of experience.

Read More: From Mold Flow Analysis to Extrusion Die Design: Enhancing Process Efficiency

Machining capability:

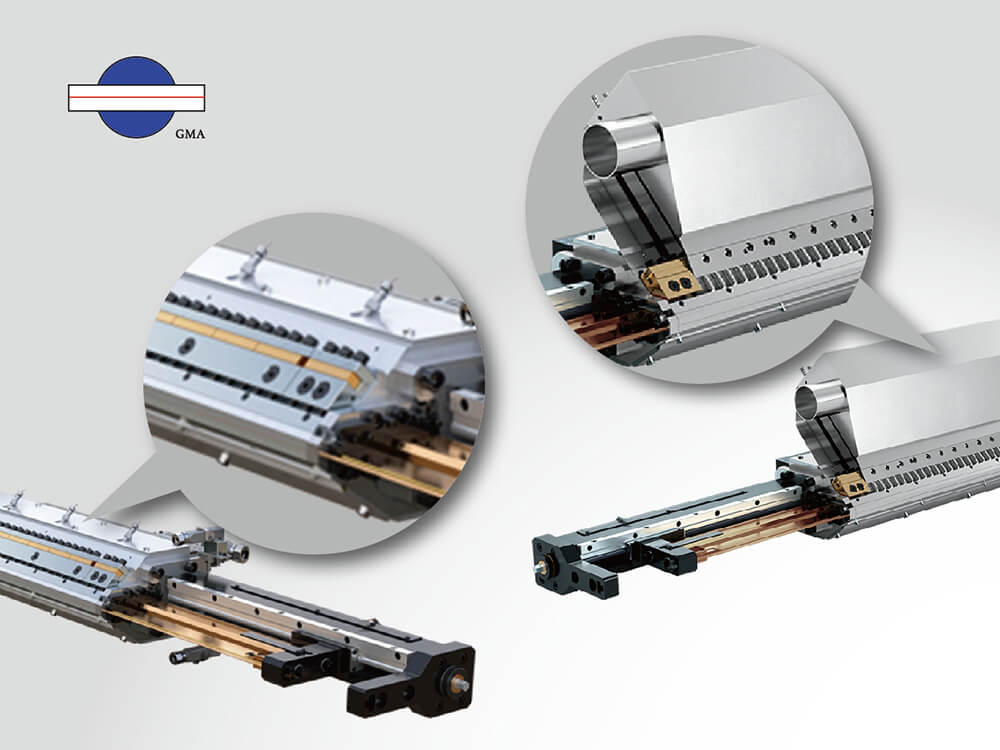

Turning a die design on paper into a physical, functional tool depends critically on machining. One of the greatest challenges in manufacturing dies specifically for melt-blown fabric lies in the long, slender nozzles. These nozzles typically have diameters of only 0.2–0.3 mm and depths of 2–3 mm—equivalent to the diameter of just five to eight human hairs. Simply identifying suitable cutting tools to drill such deep and narrow holes is already a major challenge.

A single die may contain thousands of these holes. With both the tools and the die made of steel, the process involves steel cutting steel—leaving no room for deformation or damage. As a result, success relies not only on process optimization, but also on specially designed machining tools developed specifically for this application.

These extremely difficult-to-machine long, slender nozzles require adjustments not only in the machining process, but even in the design of the cutting tools themselves.

Read More: From Functional to Precision and Durability in Extrusion Dies — CNC × Electroplating × Polishing

Process capability:

For die manufacturers, it is not necessary to operate production lines directly. However, the more deeply a manufacturer understands how those lines actually run, the better they can align with customer needs. Coating has always been just one step within a broader manufacturing process, yet because coating can deliver diverse functionalities and significantly influence final product quality, more and more R&D engineers are focusing on coating process optimization.

Even with pilot coating lines available for testing, the path to overcoming process challenges often still requires exploration and trial. In these situations, a team’s accumulated process knowledge and experience can provide comprehensive technical support. This capability is not limited to R&D alone—many customers also need to modify coating stations or replace extrusion dies to meet production-line requirements. Only by incorporating real-world production conditions into the design can customization truly and fully address customer needs.

A deep understanding of the process enables more comprehensive and effective technical support.

Read More: What Exactly Is Coating? A Must-Read for Beginners! Quickly Dive into the World of Coating

Precisely because customization is a test of comprehensive capability, a lack of experience or expertise—and the inability to anticipate potential risks—can turn customization into a disaster. True customization means evaluating different scenarios and continuously making judgments and trade-offs to arrive at a solution that is actually feasible. This is the ultimate value of customization.

When challenges become routine, every adjustment relies on teamwork.

“The success or failure of this production line is critical to us, because it determines our timing to enter the market.” This is the kind of trust entrusted to us behind every customized request. In multi-layer products, each layer may involve materials with very different properties—such as different operating temperatures, sometimes with temperature differences exceeding 30°C. Customers seek a die solution that can achieve proper layer distribution while simultaneously minimizing the risks introduced by these temperature differences.

During the early stages of communication, one solution may be proposed. However, after simulation and careful evaluation of multiple factors, an alternative approach may be chosen—one that ultimately aligns better with the customer’s real needs. From communication to decision-making, from meeting-room discussions to shop-floor manufacturing, and from design to production, all stages must be adjusted in unison.

Every non-standard customized project is a journey built on trust at every step. Experience can be replicated—but trust cannot.

Behind every customized die requirement lies a trust placed in us.

When customization becomes routine, what is truly being tested is not a single design or a one-time machining result, but whether the entire technical system is robust enough to withstand a wide range of uncertainties.

For die manufacturing, the value of customization lies in the ability to make sound judgments and trade-offs under constrained conditions, delivering solutions that can be practically validated and sustained over long-term operation—ultimately fulfilling the trust placed by the customer.