From Functional to Precision and Durability in Extrusion Dies — CNC × Electroplating × Polishing

2025.10.03Extrusion dies, also known as flat dies, require dozens of procedures from design to completion. While the difficulty of designing extrusion dies is well recognized, many people do not realize how complex and challenging the machining process can be for a die that is essentially assembled from two or more steel plates and related components. This misconception is understandable, as most people only see the exterior of a die and rarely its internal structure. Even when they do see the curved or linear flow channels inside, they may not grasp the true challenges of machining them.

In reality, die machining is a crucial step in turning a perfect design drawing into reality. It directly affects the performance of the extrusion die and the quality of the products formed through it. Any single machining step that is not executed properly can lead to various problems in the die itself.

Read more: Crafting the Perfect Extrusion Die: The Entire Process from Design to Quality Control

Every Cut Matters — CNC Machining for Extrusion Dies

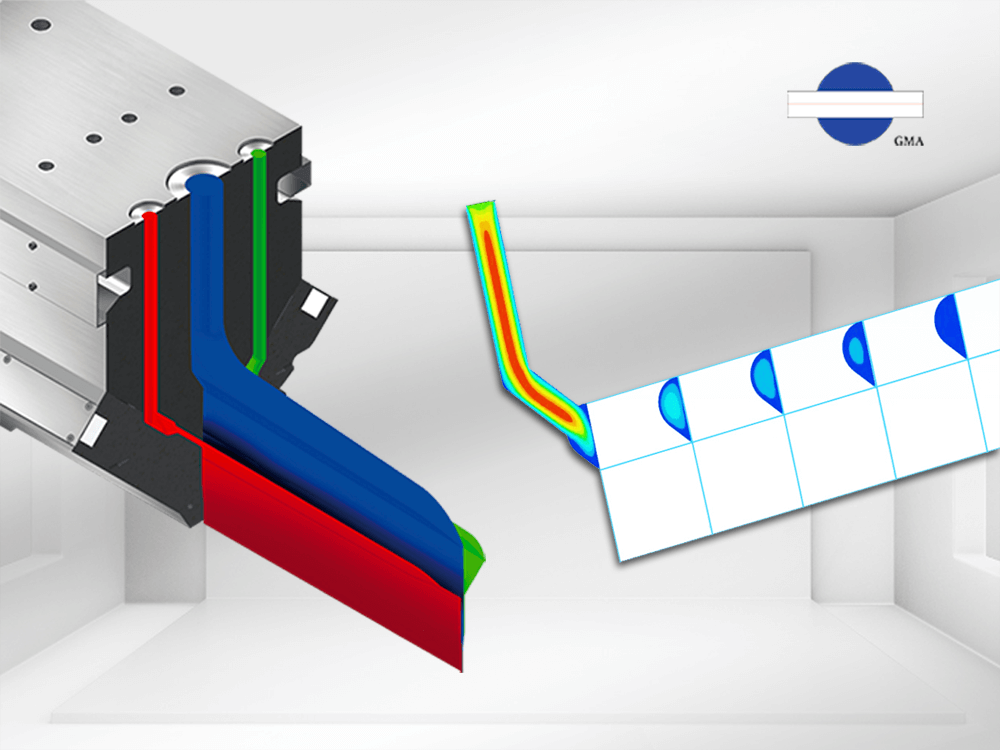

For extrusion dies, CNC machining is like the foundation of a house. The internal flow channels, die lips, and various holes of different sizes all rely on CNC machining to be completed. Since extrusion dies require machining different curvatures and depths of flow channels on flat steel plates, it means that both flat and curved structures must coexist on a single workpiece. Even the decision of which type of CNC equipment to use is itself a specialized skill.

Extrusion dies contain both

flat and curved structures, and selecting the appropriate CNC equipment alone

is already a field of expertise.

Extrusion dies contain both

flat and curved structures, and selecting the appropriate CNC equipment alone

is already a field of expertise.

Common three-axis CNC machines are not sufficient for producing the precise geometric flow channels required in extrusion dies. Four-axis and five-axis CNC machines allow the cutting tools to approach the workpiece from more angles, making them suitable for complex curved-surface machining. Higher-axis machines can also reduce the number of times a workpiece needs to be repositioned, which not only improves efficiency but also minimizes operational errors. For optical dies or high-precision slot dies, high-axis CNC machining is essential.

Multi-axis CNC equipment comes with high costs and demands advanced

programming and operational skills, yet it is indispensable for precision die

machining.

Multi-axis CNC equipment comes with high costs and demands advanced

programming and operational skills, yet it is indispensable for precision die

machining.

From Functional to Precision and Durability — Electroplating in Extrusion Dies

For extrusion dies, the primary function of the electroplated layer is to enhance surface hardness and extend service life, while also providing a protective barrier to prevent the steel surfaces from being corroded by strong acids or alkalis that may be present in plastic additives.

The slot enhances

surface hardness while also providing protective functions.

The slot enhances

surface hardness while also providing protective functions.

The complexity of electroplating is closely related to the workpiece itself. For flat workpieces, as long as issues of slot thickness at the edges are avoided, electroplating is considered the simplest and most fundamental process. In contrast, curved-surface electroplating is much more challenging, as it requires additional fixtures, auxiliary anodes, and stricter control of the plating solution.

For extrusion dies, electroplating becomes even more demanding because the workpiece inherently combines both flat and curved surfaces. On the flat areas, slot thickness must remain uniform, while on the curved sections, it is critical to prevent excessive thickness variations between concave and convex areas. At the junctions between flat and curved surfaces, uneven plating and current concentration must be avoided. This calls for specialized fixtures, multi-stage electroplating control, and sometimes even multiple electroplating cycles to ensure that both flat and curved regions achieve uniform thickness and strong adhesion.

Such composite electroplating requires extremely precise calculations and operations. While electroplating simple flat or curved workpieces may be sufficient to achieve a basic “functional” result, for extrusion dies, true durability and precision are what showcase the ultimate craftsmanship of electroplating.

Workpieces that combine both flat and curved surfaces require

composite electroplating processes to achieve the desired results.

Workpieces that combine both flat and curved surfaces require

composite electroplating processes to achieve the desired results.

Read more: Electroplating Technology for Extrusion Dies: Dual Challenges and Solutions in Modern Manufacturing

Refined Grinding Creates True Brilliance — Grinding and Polishing

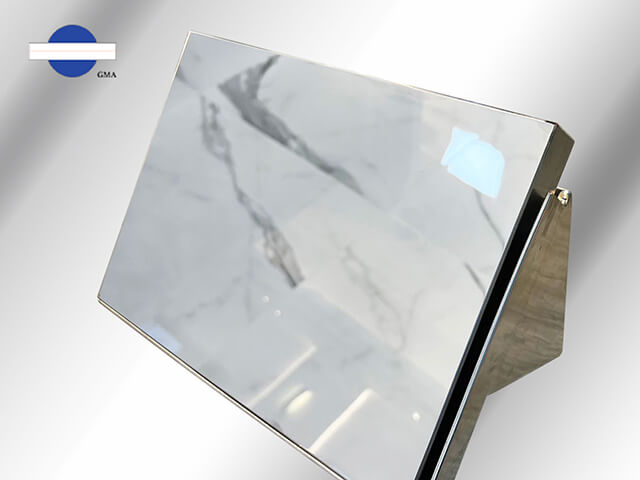

Grinding and polishing are crucial processes in both extrusion and slot dies, especially in the forming section near the die lip. What appears to be an ordinary flat surface is in fact the result of extensive grinding and finishing. The type of die steel largely determines the difficulty of grinding and polishing. Compared to the steels commonly used for extrusion dies, slot dies—often made with high-hardness stainless steel—place even greater demands on grinding and polishing techniques.

Since slot dies do not undergo electroplating, their precision and the strict surface roughness requirement of Ra 0.01 µm rely entirely on grinding and polishing. By applying multiple grinding and polishing methods, along with specialized precision surface grinders capable of controlling micro-level cutting depths, the highest degree of flatness can be achieved.

Specialized precision surface

grinding machines can control micro-level cutting depths, enabling the required

accuracy and optimal flatness for slot dies.

Specialized precision surface

grinding machines can control micro-level cutting depths, enabling the required

accuracy and optimal flatness for slot dies.

For extrusion dies that require electroplating, both pre-plating and post-plating grinding and polishing are essential to enhance the functionality of the slot layer. Extrusion dies are typically large flat workpieces with grooves and holes, often ranging from 1000 to 3000 mm in width. The wider the die, the harder it is to maintain uniform flatness, and even slight deviations can lead to uneven gloss in the plating layer.

Therefore, before electroplating, the surface must be ensured to be clean, free of impurities, and flat; otherwise, defects will become even more pronounced after plating. Pre-plating grinding and polishing must also consider slot adhesion, meaning that surfaces cannot be over-polished. Multiple stages of fine grinding and polishing after plating are required to achieve a surface roughness of Ra 0.01–0.03 µm. This ensures smooth fluid flow within the die cavity, prevents residue buildup and carbonization, and enhances the transparency and gloss of the final product surface.

Grinding and polishing play a critical role in both the pre-plating

and post-plating processes of extrusion dies.

Grinding and polishing play a critical role in both the pre-plating

and post-plating processes of extrusion dies.

Read more: Rough? Not at all! The surface roughness is more detailed than you can imagine.

The manufacturing of extrusion dies and slot dies is not simply the execution of a “design blueprint,” but rather a combination of highly sophisticated precision processes. Design is the soul of the die, while machining and fabrication breathe deeper layers of life into extrusion and slot dies. Creating a functional die is not difficult, but only a die that is precise and stable serves as the true foundation for improving product quality and production efficiency.