Key Factor for Stable Extrusion with High and Low Temperature Differences: Multi-Manifold Die

2025.08.28Company C has already placed an order for the third extrusion die designed for producing multilayer structures with high and low temperature conditions. In order to make their products more distinctive in the market and increase market share, they have made necessary adjustments in both the process and formulation. The original production line was equipped with a feed block combined with an extrusion die to manufacture multilayer products, which had delivered stable and satisfactory performance over the past years.

However, feed blocks have inherent limitations—when the flow properties of different polymers vary too greatly, operators find it difficult to control. Since the new product requires larger temperature differences due to its revised formulation, after several trials and evaluations, the customer decided to establish a new production line. Unlike the original setup, the new line will be equipped with a multi-manifold die specifically designed to handle the required high and low temperature production conditions.

Extruding multilayer products through a feed block combined with a die is the most familiar equipment configuration for most people.

Read More: Unlocking the Three Secrets of Co-Extrusion Feed block

Market Trends and Potential of High–Low Temperature Difference Products

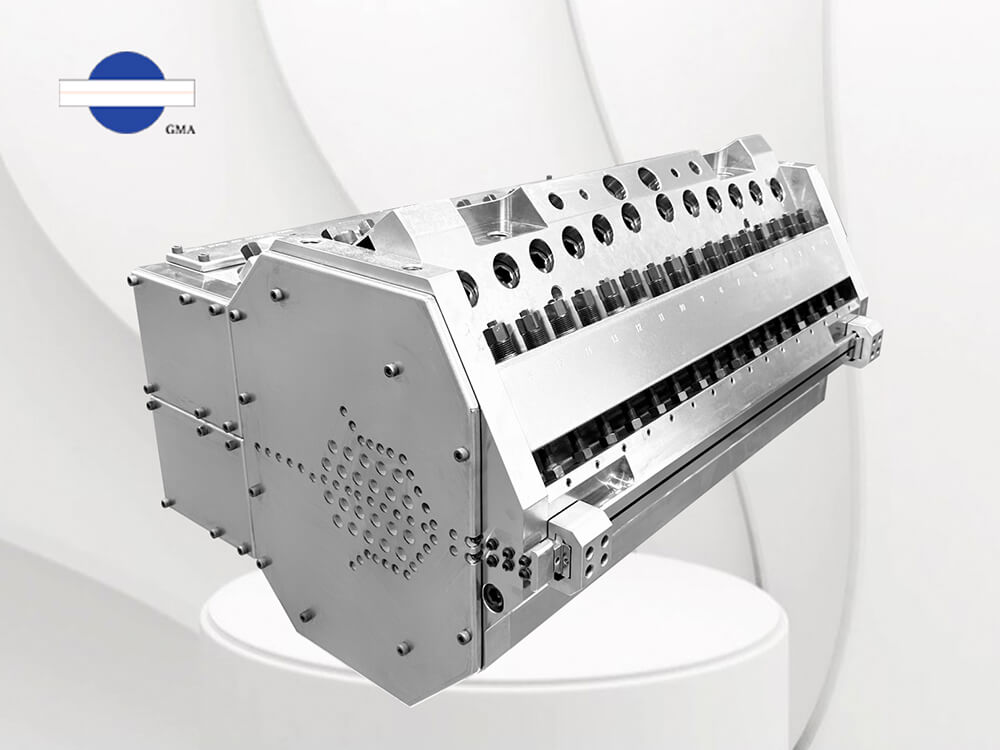

A multi-manifold die is composed of several independent cavities assembled into one tool. Polymers enter different cavities separately and only merge at the die lip outlet to form a multilayer structure. Because the independent cavity design accommodates polymers with significant differences in flow properties, companies like C, which develop new products by setting temperature differences in the process, can achieve high-quality results more easily by adopting a multi-manifold die.

Utilizing temperature differences to achieve specific product applications or functionalities has become a growing market trend in recent years. Amid global economic stagnation, manufacturers are seeking ways to maximize business opportunities with minimal investment, and adjusting production temperatures has proven to be one of the most effective shortcuts. Even if such temperature changes require replacing the extrusion die, the cost remains relatively low.

Multilayer products produced under high–low temperature conditions have a wide range of applications. Examples include improving viscosity matching (to stabilize interfacial adhesion), enhancing surface gloss (transparency or haze), increasing heat resistance, or adding other functionalities. Such products, manufactured through extrusion with controlled temperature differences, are commonly used in automotive or interior decorative panels, partition boards, insulation panels, electrical packaging materials, electronic encapsulation films, barrier films, and even sports mats—making them highly promising in terms of market potential.

Multilayer products produced with high–low temperature differences have a wide range of applications.

Read More: Innovation in Co-Extrusion Process: Multi Manifold Die

Interconnected Design of Multi-Manifold Dies

To properly handle polymers with large differences in processing temperatures, a multi-manifold die requires not only that each cavity flow channel be designed according to the material properties, but also that each cavity be equipped with an independent flow-control valve and bolt-adjustable die lip opening. In addition, each cavity has its own temperature-control system to ensure that the set processing temperature is not disrupted by long-term high-temperature operation or external environmental influences. This maintains the stability of polymer interfaces and edge materials.

As a result, every step in the development of a multi-manifold die—from design and steel selection to machining—is closely interlinked. For example, a three-manifold die may appear as a single integrated tool, but in reality, designing it requires an effort equivalent to developing three separate dies.

The design of a multi-manifold die focuses on two critical aspects: flow channels and temperature isolation. Flow channel design follows the same principle as other extrusion dies—optimized through simulation based on polymer properties. The true challenge, however, lies in preventing thermal interference between cavities during long-term production. Such interference often results from the heat generated by polymer friction, which raises the actual temperature above the set value. In addition, the external environment may become warmer after prolonged operation, further disrupting the intended working temperature. For products that must be processed under precise temperature differences, thermal interference becomes the greatest obstacle in production, and eliminating it is one of the toughest challenges for die manufacturers.

Multi-manifold dies are most commonly applied in extrusion lines where polymer processing temperatures differ by 20–50°C. Each die maker adopts different approaches to temperature isolation. Internal cavity insulation is the most basic method, while in some cases, external channels are used to introduce thermal oil cooling systems to help stabilize the cavity’s working temperature.

The independent cavity design of multi-manifold dies is all about ensuring the yield and quality of the final product.

Mold Steel with Just the Right Hardness

When selecting steel for die manufacturing, one of the most important considerations is its toughness—the ability of the material to resist cracking under impact or repeated thermal cycling. Extrusion dies, including multi-manifold dies designed for high–low temperature applications, are consistently used in high-temperature environments (typically 120–350°C, with peak temperatures reaching up to 400°C).

If the steel lacks sufficient toughness, the die may suffer from notch damage during operation (especially at the lip area) when impacted, or it may become brittle and crack under repeated high–low temperature cycles. Therefore, the choice of steel is one of the most critical factors in ensuring the durability and reliability of extrusion dies.

The selection of steel for extrusion dies, including multi-manifold dies, is closely tied to both machining requirements and actual operating conditions. Every detail in this process is carefully considered to ensure that each customer’s investment translates into value that goes beyond expectations.

Closely related to steel selection are machining considerations and the service life of the die. Many people mistakenly believe that the harder the steel, the better. In practice, however, excessive hardness makes machining operations such as milling and polishing more difficult and accelerates tool wear. Therefore, multiple factors must be taken into account when choosing steel. Typically, materials with a pre-plating hardness of HRC 33–52 are selected, followed by processes such as electroplating and mirror polishing. These treatments help reduce dead zones, minimize adhesion, and improve wear resistance—ultimately ensuring the die’s stability and extending its service life.

Read More: How to select the suitable steel to manufacturing extrusion die ?

In today’s highly competitive and rapidly evolving technological landscape, choosing the right system is essential not only to ensure product quality but also to strengthen market competitiveness. A multi-manifold die is more than just a key tool for addressing high–low temperature differences—it also represents the values of professionalism, precision, and innovation. By adhering to strict standards in every step of the process, we help customers transform ideas into tangible results, turn challenges into competitive advantages, and ensure that every investment delivers value beyond expectations.