The Invisible Guardian of Production Quality — Extrusion Die Maintenance

2025.10.31The Redefinition of Extrusion Die Maintenance

Most people still perceive die maintenance as something done only when a die breaks down. However, in today’s market—where both production efficiency and product quality are equally critical—die maintenance has been redefined as the balance point and starting line for quality and efficiency improvement.

It’s much like regular health checkups for people: you don’t wait until you feel unwell to see a doctor. Through scheduled inspections, you can detect subtle changes before problems arise—and even better, by collecting data and analyzing related information, you can predict potential issues and take preventive measures in advance.

Die maintenance is the balance point and starting line for the evolution of quality and efficiency.

Based on long-term observation of

extrusion die users, it has been found that while most die damage results from

natural wear and environmental factors, the more critical elements are maintenance awareness and timing.

Every maintenance decision directly affects production line stability, product yield, and overall

competitiveness.

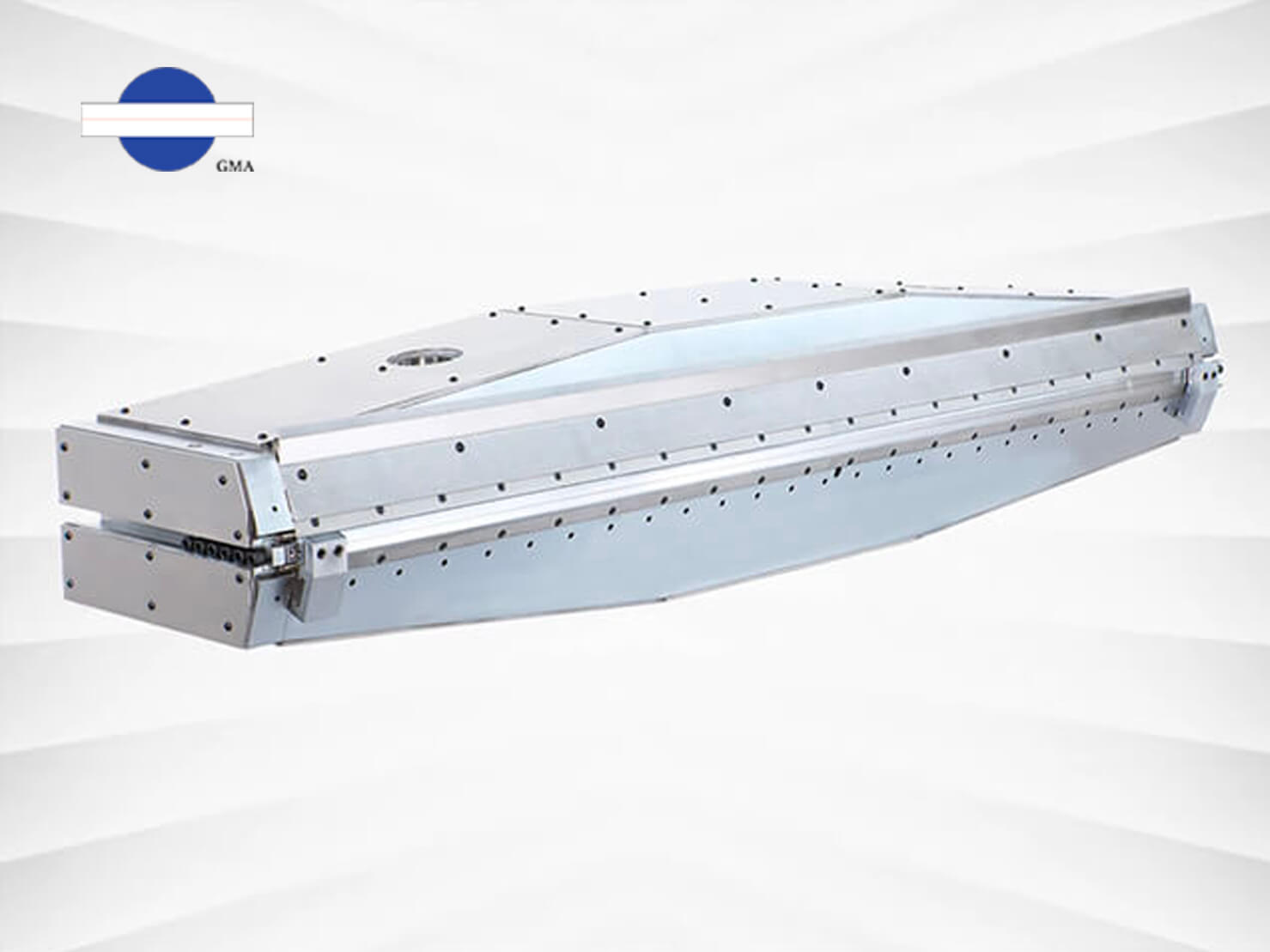

It’s not surprising that more and more companies are allocating budgets for annual maintenance of extrusion dies, since an extrusion die is essentially the soul of the production line—its condition determines the rhythm and stability of production. In this sense, die maintenance serves as the invisible guardian of production stability.

Extrusion Die Damage Analysis: Only Those Who Truly Understand Dies Can Repair Them Well

|

Die Damage Phenomena |

Possible Root Causes |

Description |

|

Flow Channel Scratches, Die Lip Wear, Chrome plating Degradation, Uneven Extrusion, and Thickness Variation |

Excessive Polymer Flow Velocity |

From the die inlet to the outlet, if the polymer flow velocity is too high, it exerts strong shear forces on the flow channels it contacts. This can cause surface abrasion or local overheating due to frictional heat, leading to surface roughening and degradation in the flow channel and die lip regions. |

|

Cracks or Scratches on the Die Surface, and Damage to the Chrome plating |

Mechanical Wear Caused by Filler Materials |

The filler materials in the production formulation can cause mechanical abrasion effects. |

|

Surface Cracking, Fatigue Delamination at the Chrome plating Interface, and Steel Deformation |

Thermal Fatigue Caused by Cyclic Heating and Cooling |

During extrusion, the die undergoes repeated cycles of high-temperature production (operating at 200–400 °C) and low-temperature standby ( dle at around 25–40 °C). This temperature fluctuation causes thermal expansion and contraction differences between the die’s surface and its internal structure due to uneven coefficients of thermal expansion, leading to internal stress accumulation and eventual material fatigue. |

|

Corrosion of the Chrome plating or Flow Channel Surface, Causing Die Flatness Deformation, Uneven Extrusion, Surface Black Spots, and Flow Marks |

Chemical Residues and Carbon Build-up from High-Temperature Production |

During long production runs, polymer materials can

undergo oxidation and

thermal degradation at high temperatures, resulting in the

formation of carbonized

residues.

|

All of the above are issues that gradually accumulate in extrusion dies during long-term production. Therefore, regular die cleaning and maintenance are extremely important. Otherwise, by the time visible damage or peeling appears, it will require much higher repair costs.

Case Example:

A customer’s extrusion die showed surface damage inside the flow channel, resulting in uneven extrusion thickness.

After repair and re-polishing, the die achieved a straightness of ≤ ± 2.5 µm/M, and the flow channel surface roughness reached Ra ≤ ± 0.02 µm.

Only Those Who Truly Understand Dies Can Repair Them Well

Die Maintenance: Only True Expertise Can Bring a Die Back to Life

Compared with manufacturing a brand-new extrusion die, die maintenance is far more challenging. Even when the original manufacturer services its own die, it is often difficult to fully understand the die’s actual operating conditions—including factors such as operator handling, environmental humidity and temperature, or changes in material formulations.

These unknowns make it harder to accurately determine the root cause of damage, meaning that solutions can only be developed based on visible surface symptoms.

In fact, some manufacturers even refuse to provide maintenance for dies produced many years ago, showing just how demanding—and often thankless—the work of die maintenance truly is.

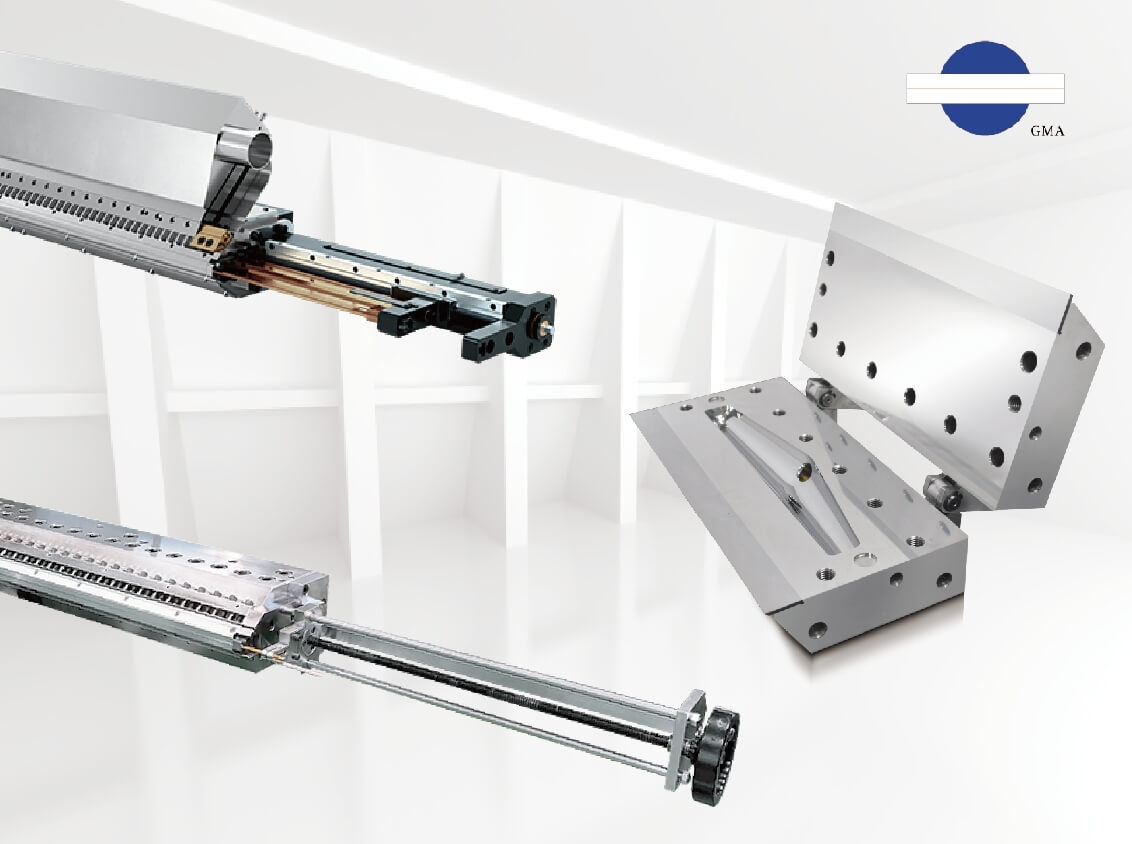

The most challenging part of die maintenance is repairing dies manufactured by other companies. Without knowing the type of steel used or the original machining process, many more variables must be considered when developing an appropriate repair strategy.

Without sufficient expertise and experience, it is extremely difficult to

master the proper restoration techniques.

Many people hold the misconception that any skilled machinist can easily repair

a die, but in reality, die restoration involves far more than

machining alone.

Only those with extensive

experience and in-depth knowledge of extrusion dies can perform

repairs that truly bring

the die back to life.

The typical process of die maintenance usually involves the following steps:

Provide inspection reports before and after maintenance for die users as a reference, helping them establish a die maintenance record, which contributes to long-term maintenance and service planning.

Die maintenance also requires multiple detailed procedures to ensure a complete and proper restoration.

Read more:All extrusion die issue , let GMA help you.

The Core of Maintenance Management: From Reactive to Preventive

Die maintenance focuses on repairing damage, but if we extend the definition of “maintenance,” the care and upkeep performed before a failure occurs can be considered preventive maintenance. This approach is the true key to keeping an extrusion die stable and extending its service life.

It’s just like a vehicle that requires regular inspection and servicing after delivery—to prevent unexpected breakdowns caused by hardware or mechanical issues during operation.

Recommendations for Preventive Maintenance of Extrusion Dies:

1.Establish a Die Maintenance Record:

Document essential information such as production date, operating hours, production output, and all previous maintenance records.

2.Set a Regular Inspection Schedule:

Define routine in-house cleaning intervals and schedule annual factory inspections and servicing.

Regular preventive maintenance can extend die service life by 10–20%.

3.Predict Maintenance Timing:

By digitalizing and analyzing data such as usage hours, production volume, and in-house maintenance records, die users can predict potential wear periods and plan maintenance proactively.

Establishing Preventive Maintenance Through Digitalized Die History

Records

Establishing Preventive Maintenance Through Digitalized Die History

Records

Die maintenance represents the technical expertise of the die manufacturer, while preventive maintenance (regular servicing) reflects the management intelligence of the production side. A well-structured die maintenance program can reduce downtime, maintain high yield rates, and minimize emergency repair costs.

Technological Innovation: Continuous Advancement—Professional Die Maintenance for More Reliable Production

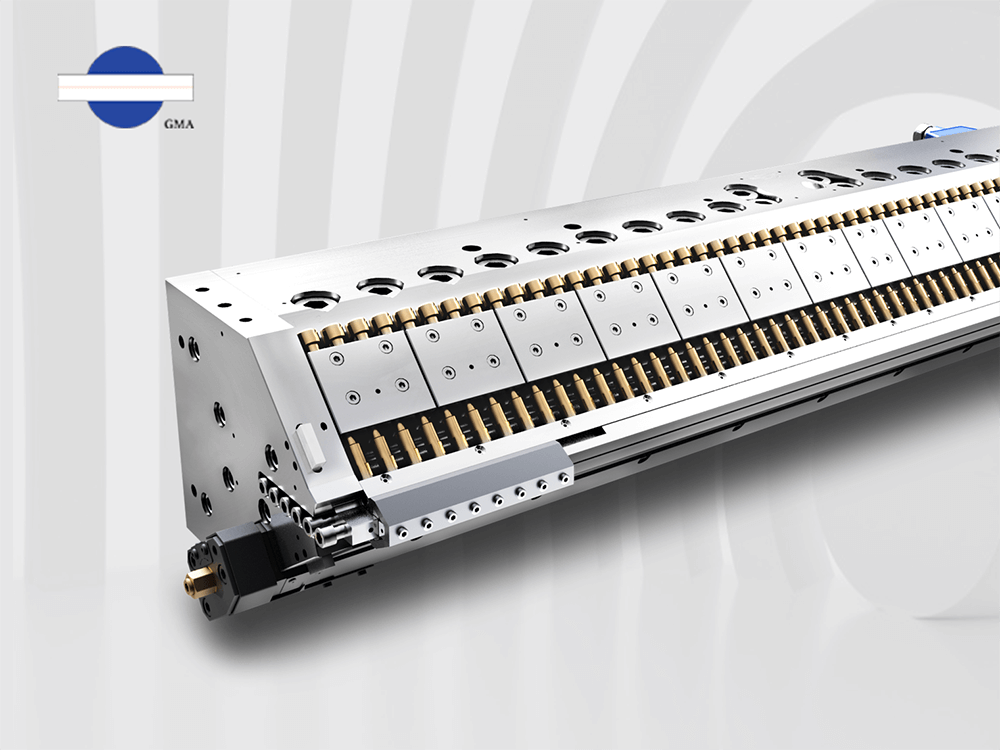

To help users resume extrusion die production as quickly as possible, extensive machining experience and professional expertise in extrusion dies have led to the development of various repair techniques.

For instance, precision repair methods for minor damage can shorten the restoration period to within one week.

For flow channel surface restoration, improvements in chrome plating processes and advancements in grinding and polishing techniques are key factors in enhancing die repair quality.

Combined with instrument-based inspection and data collection, these efforts enable the establishment of a comprehensive database—facilitating continuous tracking and the formulation of effective repair strategies.

Only Continuous Advancement in Professional Die Maintenance Can Ensure

More Reliable Production

Only Continuous Advancement in Professional Die Maintenance Can Ensure

More Reliable Production

Read more: Do you know 5 points of extrusion die repair and maintenance?

The true value of an extrusion die supplier lies not only in design and manufacturing, but also in the ability to provide users with comprehensive die repair and maintenance support. Each die restoration is not merely about replacing components or bringing a die back to life—it is about safeguarding the stability of the entire production line.

A well-established and complete die maintenance support system can reduce the likelihood of damage, lower production costs, and maintain consistent product quality. Every extra effort invested in extrusion die maintenance is an added layer of assurance that keeps the production line running longer and more stably—and every extra investment in maintenance is, in fact, an investment in greater product value.