How to select the suitable steel to manufacturing extrusion die ?

2023.04Most people have such experience to enjoy nice cuisine, behind each delicious dish, besides the chef good skill, ingredients are very important, it is the base of dish. same with an extrusion die, not only excellent machining skill and design, how to pick appropriate steel, that is a kind of professional knowledge.

Some points to be considered, when we pick appropriate steel for extrusion die.

First, the working condition of extrusion die , including temperature, pressure etc.

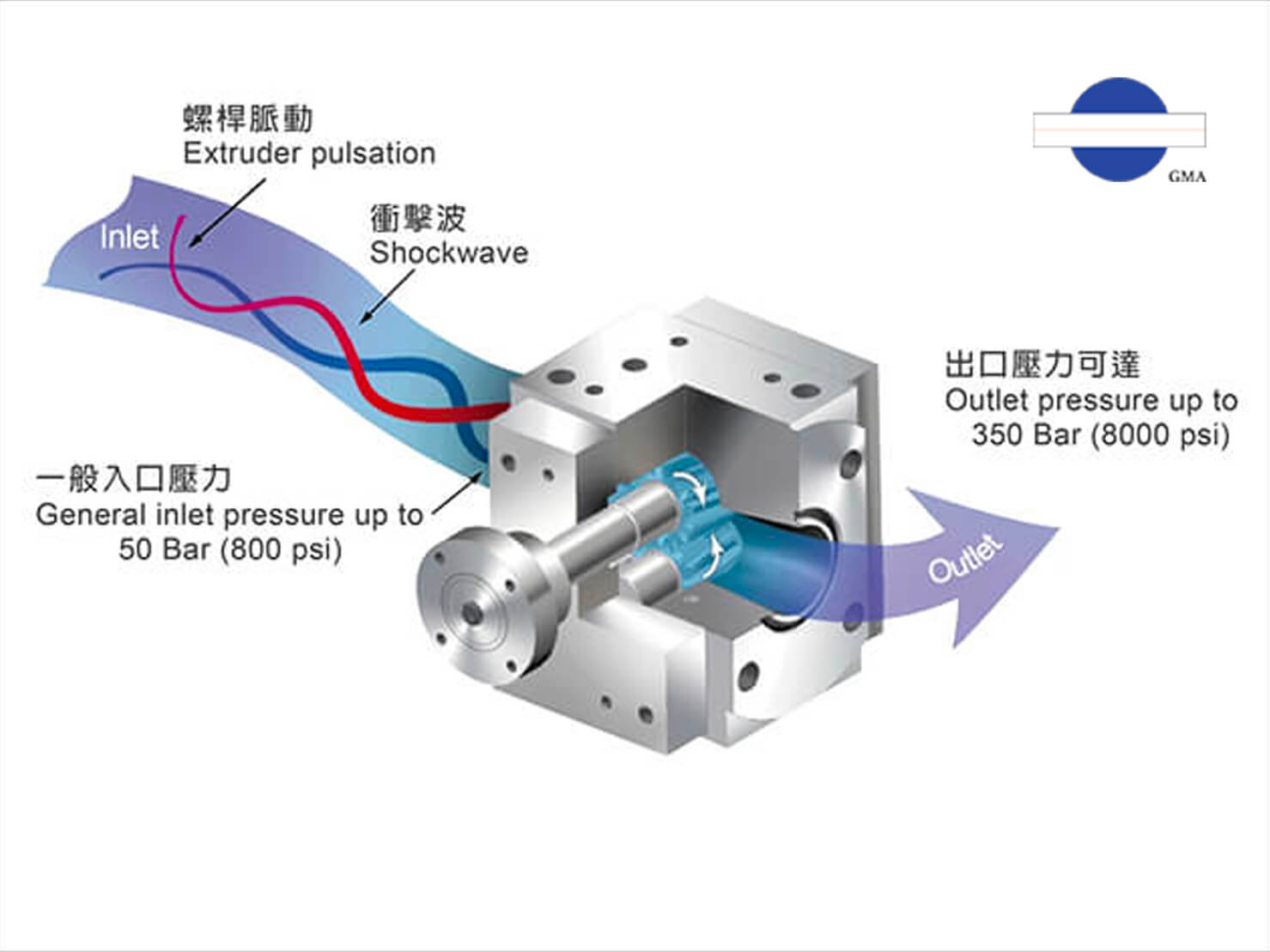

Process will be different due to different product, extrusion dies are used for various of production lines with different setting condition, mostly, the working temperature is around 250~350℃, but for some special process, the temperature may be higher to 450℃, some process may be working under high pressure before the extrusion die, mostly, the pressure before the die is around 100-250bar. Extrusion die is working under high temperature and pressure, the stability and tolerance of steel is the first point to be considered.

Second: Machining way of extrusion die, including CNC processing, chrome plating, grinding, polish etc.

Most people have such misunderstanding: Harder steel with better tolerance. Actually, how to pick appropriate steel is based on application. For making extrusion die, usually we select the steel hardness around HRC28~40, this is not too difficult to any machining process, including machining channel, drill holes etc., hardness more higher, more difficult for machining, more damage but poor quality, some too hard steel even can’t be processed.

( How to maniching is important consideration, when we select the steel. )

From 2023, we found better steel, modified BPM series steel, the cost is higher, compared with 2311, but better stability, higher hardness (HRC38-40), after polish process, the surface is better than 2311 steel, the best part is BPM steel with excellent temperature resistance and 30% faster heat conduction, currently, everyone want to save energy and cost, extrusion die made of BPM steel can help user to save a lot electricity.

Besides machining, plating is important process of extrusion die. The chrome layer is for reducing coefficient of friction between die surface and plastic, to avoid die line, it is important to film manufacturer. Before the chrome plating, polish quality is better, the chrome layer will be better, this is the reason why we pick BPM steel to make die, due to the good performance of polish process.

(Polish quality before the chrome plating is better, the plating layer is better. )

Another consideration of long term usage of extrusion die, based on our decades refurbish die experience, no matter which brand die, if the steel of die is not appropriate, it short the lifetime of die, meanwhile, it makes more difficult of repair, even it can not be refurbished.

For users, extrusion die is made of appropriate steel may least lifetime and avoid high maintenance and repair cost.

Third: Adaptability of extrusion die and polymer

For special polymer or formula user, we will adjust the design and process of extrusion die, at the same time, we may consider to use different steel to make die for getting better performance. For example, PVC—corrosive polymer, 2316 series steel with chrome plating is the best treatment to the die. 2316 steel is with good preservative, and we can get good mirror polish quality not too difficult, for users, they don’t need to worry to find suitable die because of using PVC.

Compared with PVC, some formula contains fluorine, stronger corrosive, 2316 may be not appropriate, we will consider C276 steel, it is with the best anti-corrosion property, but C276 is called “devil steel” due to quite difficult machining process. Even though we have over 30-year experience, we still spend a lot of time to find the best machining condition to C276, for making good die that meet customer’s expectation.

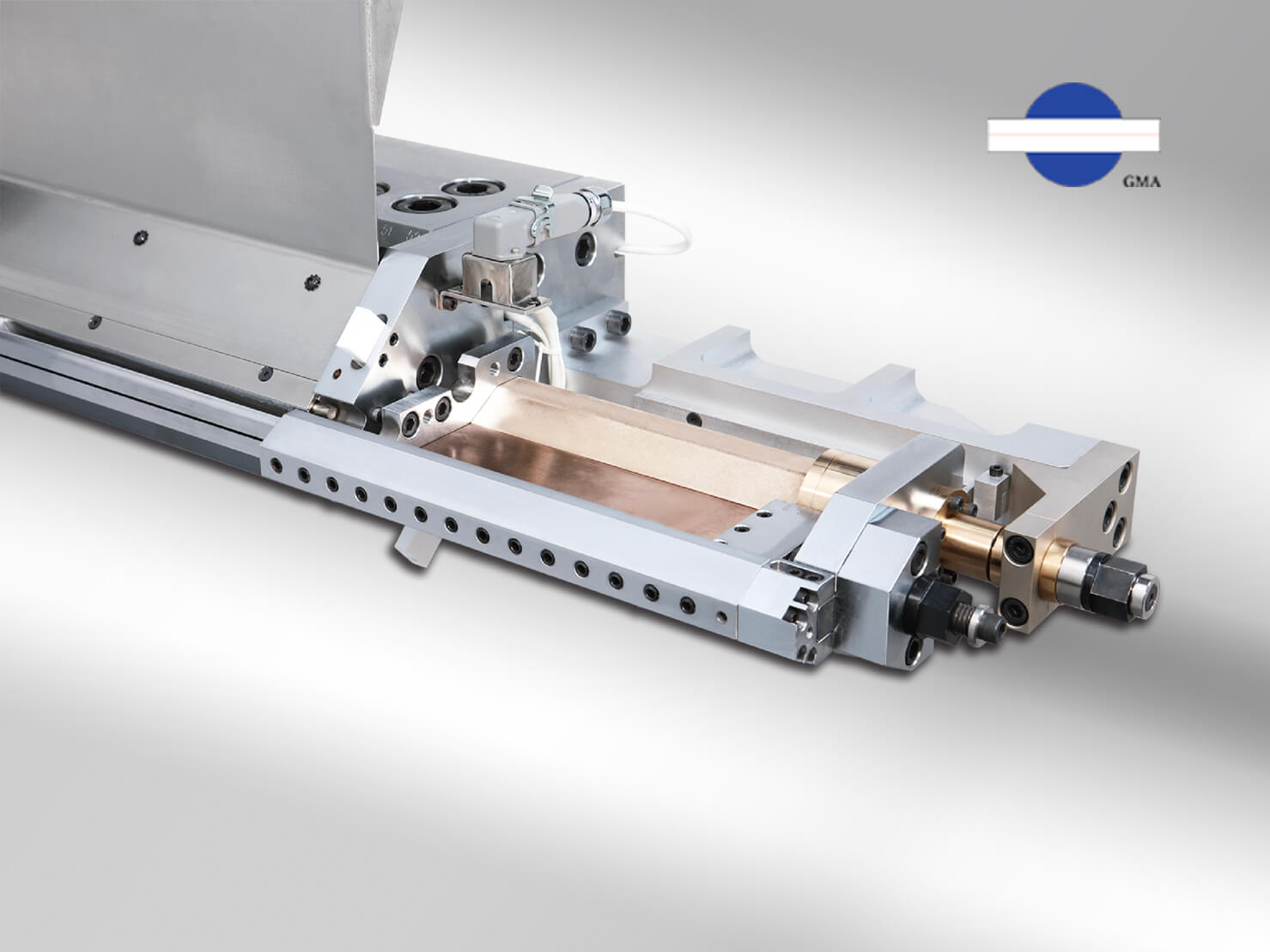

(Left: Most people know die steel is 2311 serial. Right: Extrusion die made of C276 is for process fluoroplastics. )

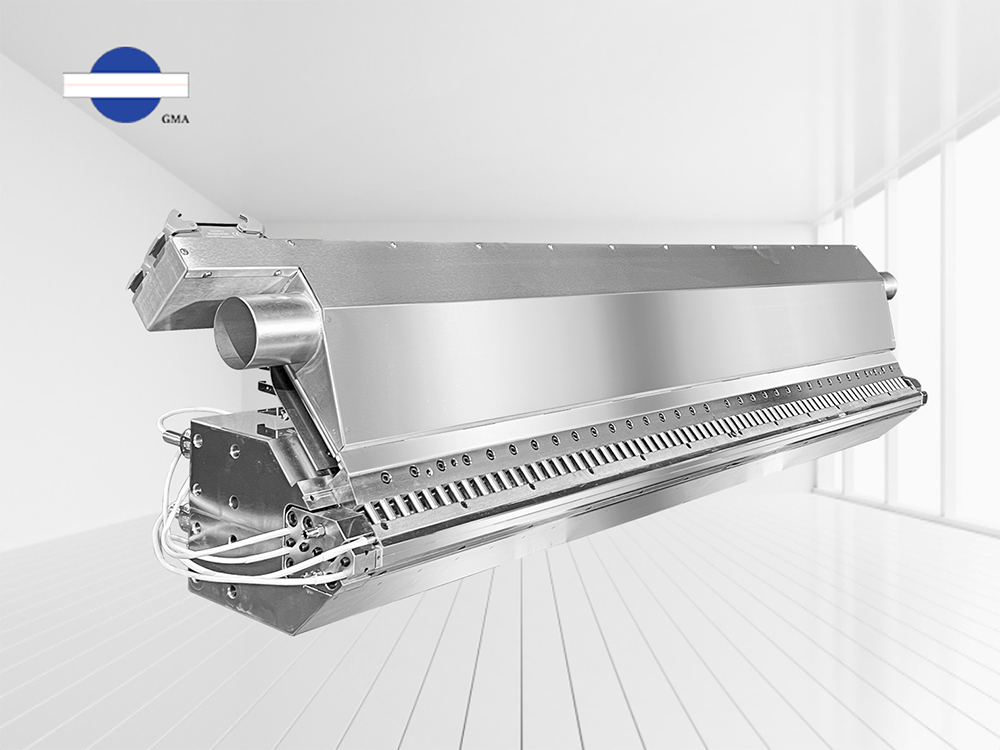

Besides extrusion die, for slot costing die, we also spend much time to select the suitable steel, there are quite difference of usage of extrusion die and slot coating die, for example, slot coating die working temperature is mostly room temperature, viscosity of gel are different, some of gel is high corrosive, meanwhile, we have to consider the process after coating etc. Good polish precision, shape radius of lip is basic standard of coating die. We are not only to adjust the processing for coating die, also use W8PH serial steel for it, due to the steel is with excellent corrosion resistance, good and stable mechanical behavior.

(Left: BPM steel is used for making extrusion die. Right: W8PH is used for making coating die. )

Steel to die is just like rebar to house, if the foundation is not steady, it can not be used for manufacturing good extrusion die. There is no good or bad steel, how to select the most suitable steel from among hundreds of steel is a professional skill of die manufacturer, this ability is essential that to ensure that customer receive the best quality extrusion die.