Behind the Light : Quality Commitment and Technology Behind Optical Products

2025.12.31Smartphones, computer and television screens, smartwatches, tablet devices, LED lighting, automotive paint protection films and heat insulation films, medical imaging displays, as well as various human–machine interfaces may appear unrelated at first glance. Yet, these products share a common characteristic: they are all closely connected to optics.

They exist throughout our daily lives—and are often used every single day—while being inseparably linked to optical technology.

Optics is widely applied in the everyday products around us.

In simple terms, optics describes how the human eye perceives light, and more fundamentally, it is the science of controlling how light is generated and transmitted.

For example, why does a computer screen appear bright without being harsh to the eyes? Why can a smartphone display remain visible under sunlight? Why does an in-vehicle instrument panel avoid glare? Why do LCD televisions present vivid and saturated colors? And why can anti-glare lighting fixtures help protect our eyes?

All of these products rely on optical materials to achieve functions such as light diffusion, light guiding, and brightness enhancement. Through dedicated designs, these materials precisely control the direction, intensity, and distribution of light.

Therefore, optics can be understood as the integration of materials × processes × precision control.

No one would accept an LCD display with dull colors, insufficient brightness, or a screen that appears bright in the center but dark around the edges. This is why LCD displays rely on a carefully layered optical film stack—typically including a reflector film, light guide plate, diffusion film, brightness enhancement film, and the LCD panel itself—to transform light through the specific function of each layer into a uniform brightness suitable for human vision.

Because optical applications demand an extremely high level of precision and fine control, optical products may look similar to ordinary sheets or films at first glance, yet their quality requirements are fundamentally different. While the production yield (usable rate) of general products can typically reach 90–95%, the yield of optical products, even under mature manufacturing conditions, averages only 70–85%, clearly reflecting the exceptionally high acceptance threshold and the significant technical challenges involved in their production.

|

Criteria for acceptance |

General Products (sheet / film) |

Optical sheet / film |

|

Appearance |

Dimensions meet specifications; minor defects are acceptable (e.g., slight flow marks that are not easily noticeable by visual inspection) |

Visual inspection combined with optical instrument inspection; no defects, dark marks, or surface luminance non-uniformity are acceptable. |

|

Thickness tolerance |

General sheet /film +/-30-100um Functional film +/-10-30um |

Optical sheets: average +/-5-10um, Optical film: average +/-0.5-3um |

|

Yield(under mature manufacturing condtions) |

General sheet /film 95-98% Package film over 95% Functional film 92-97% |

Optical film (diffusion, brightness)) 70-90% Optical sheet(diffusion, light guide) 65-90% High-end display product: 70-85% |

Therefore, for optical products, the maturity and stability of the manufacturing process must rely on precision equipment structures. Equipment used in optical applications must be designed and manufactured under the same highest inspection standards as the optical products themselves.

The Perfectly Balanced First Step: Meticulous Design

For optical products, the primary requirement is thickness uniformity, and most optical applications also demand high transparency. From the perspective of extrusion die design, this means that the flow channel must allow the polymer melt to be evenly distributed and properly extended within the die cavity. Multi-manifold direct dies are therefore commonly adopted, with the main objective of ensuring consistent flow velocities for materials with different properties and maintaining balanced melt pressure, so as to achieve fundamental thickness uniformity.

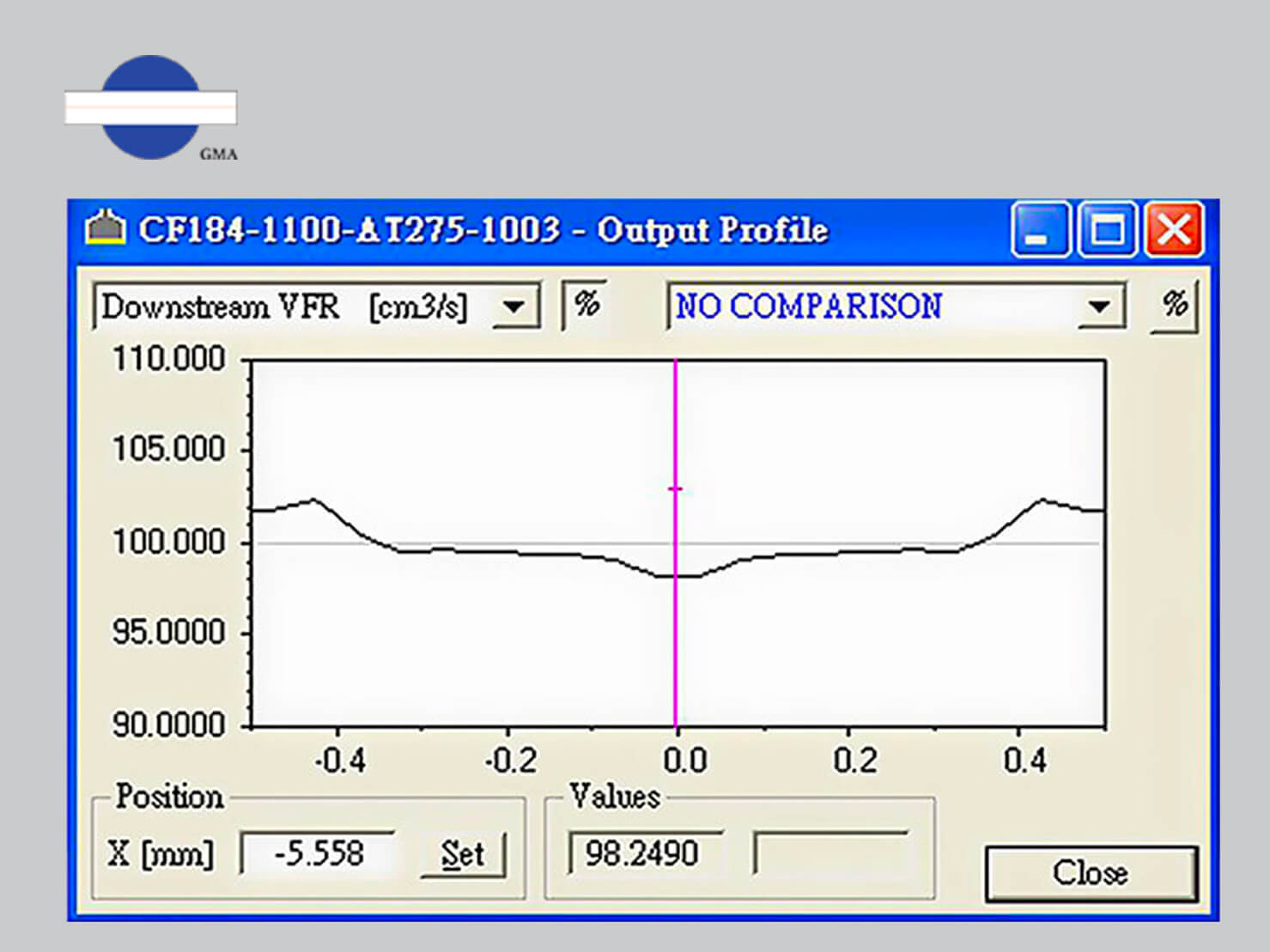

High-precision die lip gap adjustment mechanisms are another critical factor in controlling thickness uniformity. Optical production lines are typically equipped with online thickness measurement systems to continuously monitor whether the product thickness remains within the allowable tolerance range. Traditional manual adjustment methods can no longer meet the stringent requirements of optical film production. As a result, optical film lines almost exclusively employ automatic dies, enabling real-time, fine-tuned adjustments during production to ensure stable and consistent quality.

Every step in the design process is closely interconnected, and every detail exists for one purpose only: to achieve perfect balance and uniformity.

Dies used for optical applications must also undergo multiple, strictly

controlled manufacturing and inspection processes.

Dies used for optical applications must also undergo multiple, strictly

controlled manufacturing and inspection processes.

Read More: Innovation in Co-Extrusion Process: Multi Manifold Die

Precision Machining Enables Premium Quality

Even the best design cannot result in equipment capable of stable production without the corresponding machining experience and expertise. The selection of steel materials must offer stable and controllable deformation characteristics in order to maintain long-term stability under high-temperature operating conditions. CNC precision machining plays a critical role in ensuring that the curvature and depth of the flow channels conform precisely to the design, making multi-dimensional tolerance inspections an essential process.

The surface roughness inside the die cavity—measured using optical instruments—must be controlled within Ra 0.01–0.03 μm, while the radius of the die lip edge must be maintained within 20–40 μm. Achieving these requirements depends on the support of precision grinding equipment combined with mirror polishing processes. As a result, the manufacturing procedures for optical dies are far more extensive than those for general dies, and the required production time is correspondingly longer. Any overlooked detail at any stage of the process can directly impact the final product quality.

A well-conceived design must be matched by equally capable precision

machining.

A well-conceived design must be matched by equally capable precision

machining.

Read More: Crafting the Perfect Extrusion Die: The Entire Process from Design to Quality Control

Enhancing Optical Products to the Next Level — Coating

As mentioned earlier, manufacturing processes are a critical factor in determining the quality of optical products. Beyond hardware equipment, these processes also encompass the actual production procedures. Coating is one of the most widely applied processes in optical products. When optical functions require greater precision and stability—while also addressing increasing market demands for customization—certain optical performances that were traditionally achieved by stacking optical films, such as anti-glare coatings, hard protective coatings, and anti-reflection coatings commonly used in various display applications, are now increasingly realized through coating processes.

By adopting coating technologies, optical products can achieve enhanced functionality, more precise control over light, and greater flexibility in adjustment. This evolution explains why coating processes have gradually shifted from a supporting role in the past to becoming one of the core technologies defining optical performance today.

Read More: What Exactly Is Coating? A Must-Read for Beginners! Quickly Dive into the World of Coating

The coating process enables optical products to achieve stronger and more advanced functional performance.

Coating can be achieved through various methods, among which roll-to-roll (R2R) coating systems are the most widely used. This is mainly due to several key characteristics of roll-to-roll equipment:

1. Continuous production capability

With stable control of web tension and line speed, continuous production helps prevent thickness fluctuations and avoids thickness inconsistencies between the edges and the center of the coated surface.

2. Improved thickness uniformity and precision through versatile coating stations

By utilizing multi-functional coating stations—such as slot dies, micro-gravure rollers, and comma coaters—product thickness can be controlled more easily and accurately. When optical films are stacked layer by layer, each additional layer inevitably introduces another source of error. Even if the error of each layer is minimal, the cumulative effect can be significant. In addition, issues such as interlayer adhesion and warpage must also be considered. By adopting coating processes instead of lamination, the risks associated with stacking can be reduced to a simpler consideration of compatibility between the coating layer and the substrate, making process control more manageable for operators.

3. Flexibility to produce multiple products on the same production line

A single coating line can be adjusted to accommodate different production conditions or a variety of products. Compared with lamination, which makes it difficult to modify specifications or optical designs and thus limits responsiveness to diverse market demands, coating processes allow greater flexibility through adjustments in coating thickness and width. Moreover, with appropriate line design, one coating line can be used to manufacture a wide range of products. For example, an automotive paint protection film (PPF) coating line can be equipped with additional modules to produce higher-consumption window films, or the same coating line can be used for diffusion, anti-glare, and anti-reflection coatings.

The stability of continuous roll-to-roll production

has therefore become the mainstream approach in optical coating applications.

The stability of continuous roll-to-roll production

has therefore become the mainstream approach in optical coating applications.

Read More : The Ultimate Craft Hidden in Daily Life: A Journey Through Roll-to-Roll Coating Technology

In addition, other common optical coating applications—such as optical sheets, glass substrates, high-precision optical components, or optical lenses and filters—typically adopt sheet-to-sheet coating or vacuum deposition processes. However, due to the advantages described above, roll-to-roll coating has become the mainstream in optical manufacturing, particularly for its ability to achieve precise thickness control under stable line speed and tension conditions.

Optical products have long been deeply embedded in our everyday lives. However, the high entry barrier of optical products is far from easy to overcome. In the world of optics, the focus is not on pursuing extreme specifications, but on whether stable production can be consistently achieved and whether every detail can withstand the test of long-term mass production.

From materials and processes to precision control, it is this comprehensive set of requirements that truly determines optical quality. Through different types of equipment—such as optical extrusion dies, coating dies, and coating systems—optics is transformed into tangible products.

“Yes, it’s that light.”

Behind that light lies the spirit and dedication of countless professionals who relentlessly pursue refinement and precision.