Want to enhance R2R coating quality? You must to know SMART rules.

2023.03More and more electronic product, such as LED、circuit board、solar battery、energy storage battery etc., for improving production capacity and quality , meanwhile saving cost and optimized processing, most manufacturers try to find solution, includes revised equipment, purchase new production line, operation condition adjustment or formula etc..

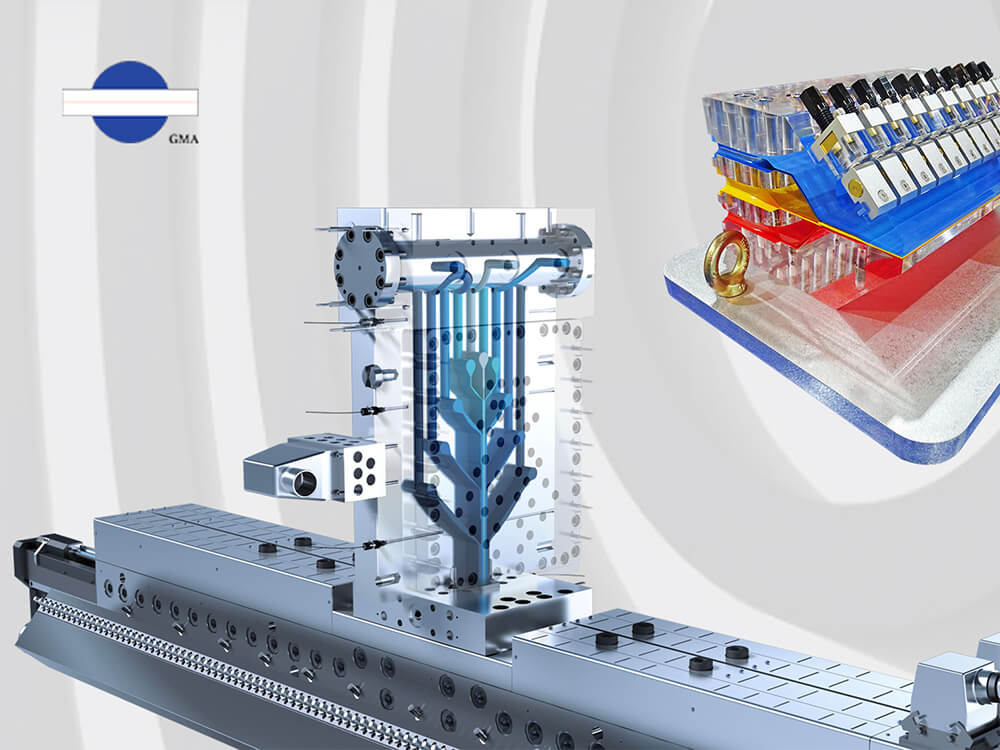

Roll to Roll (R2R) equipment is the most popular and best solution, coating is key factor in the processing, how to choose the suitable equipment is another issue.

( R2R equipment is the essential element to influence battery coating quality. )

SMART rules help you to find the best R2R.

Simple—intuitive operation

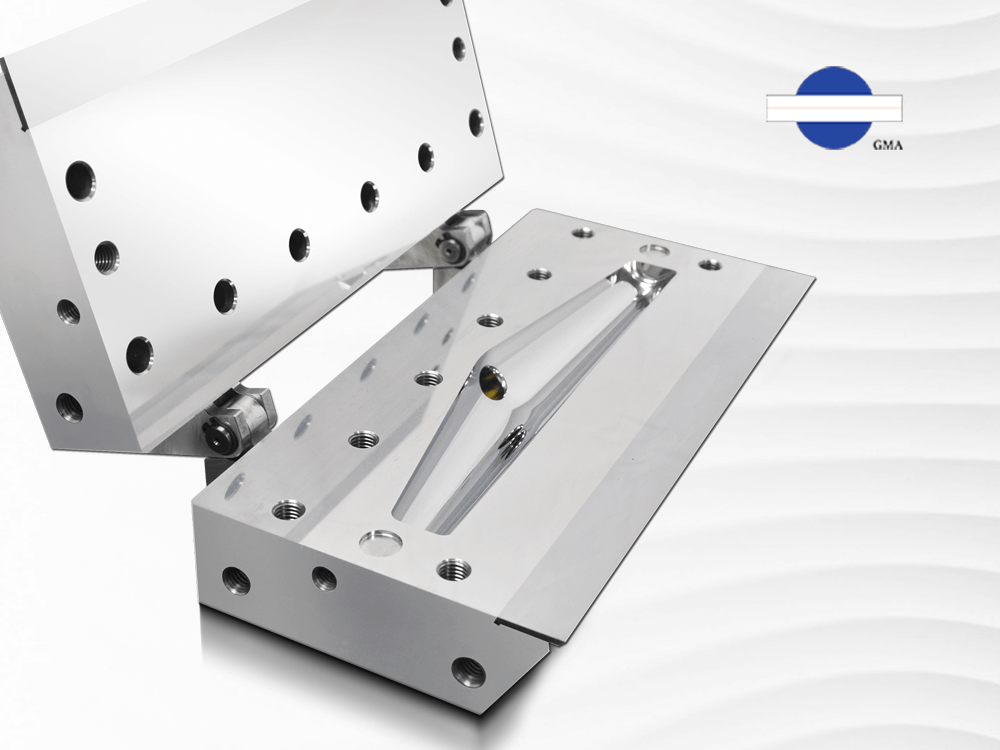

Easy to use operation panel is a standard device for R2R equipment, besides that we have to consider long time maintenance and cleaning. The time cost is kind of invisible, it is easily ignored by the manufacturer, especially the time cost of maintenance and cleaning.

For operators, easy-to-do maintenance and removing the device for clean is very important, as that can save their time and energy, meanwhile, enough space for them to do these is necessary, especially when emergency troubleshooting happens, some device may be removed or disassembled.

( Simple operation panel saves workers time. )

Mechanical unit arrangement

R2R coating line including several unit, such as : rewind and unwind、oven and tension control system etc., meanwhile water or power supplier and environment condition are considered, these are relative with unit arrangement.

All units should be shockproof, to avoid these units affect each other, when the production line is running. The affect may cause material wrinkle or broken, and poor coating quality. Actually, these problems can be solved by well design.

( The appropriate mechanical unit arrangement reduces production variation. )

Accuracy

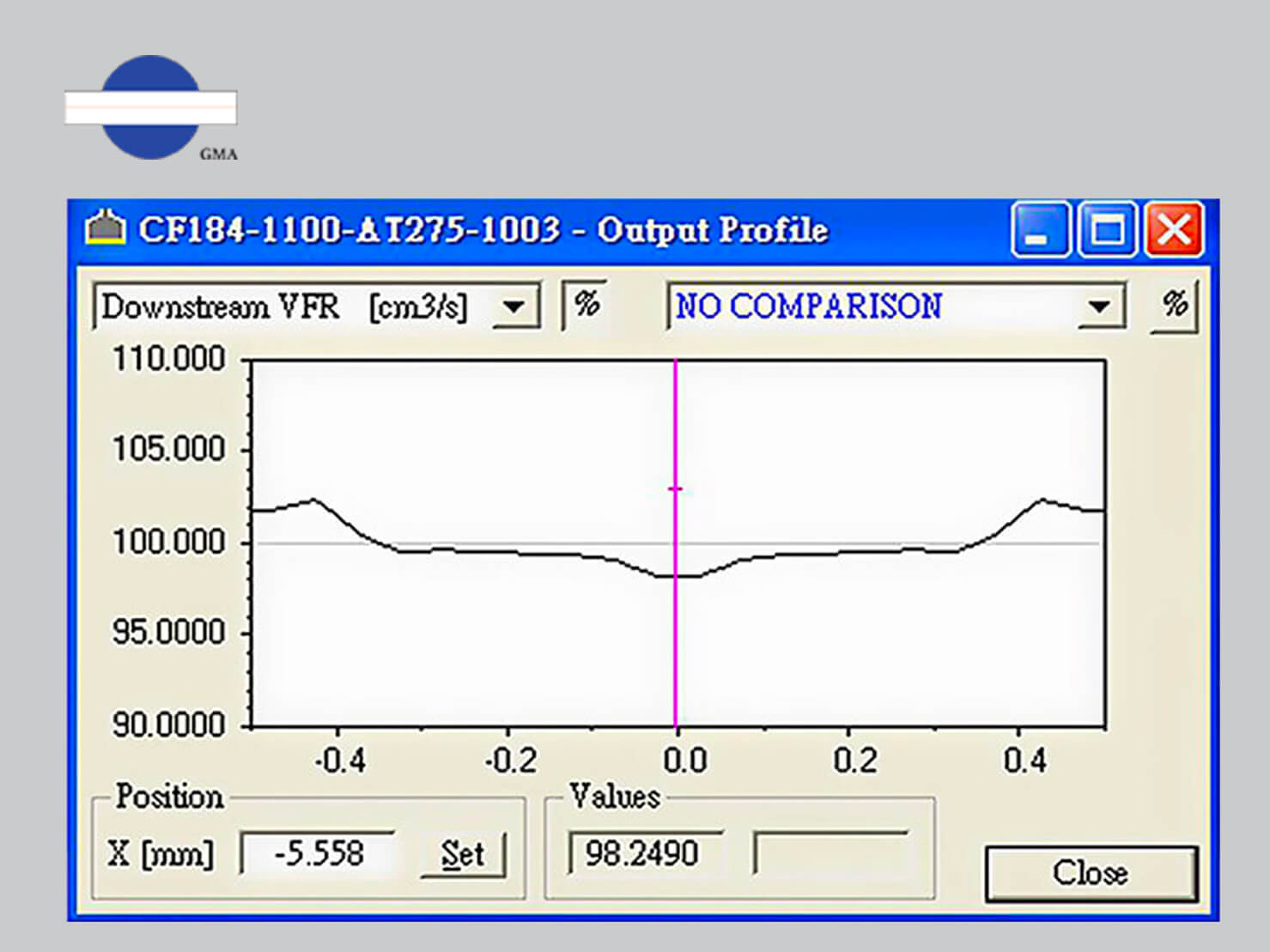

No doubt, Accuracy is the basic and the most important requirement of coating. In R2R production line, besides unit arrangement, there are some factors that may affect accuracy.

For example, precise rewind and unwind posting is to avoid dislocation between base material and glue, or base material broken, at the same time to ensure even coating.

On the other hand, keeping stable tension is also very important, as how to control tension in different units, which will be the essential factor of R2R equipment.

( Accuracy is the basic and the most important requirement of coating. )

Recycle and Reuse energy

High inflation brings increasing cost pressure, manufacturers try to find a way to reduce the consumption of water or electricity. The oven unit of R2R line needs a lot of electricity for running, nowadays, advanced R2R equipment saves energy function, recycles warm air in front and rear of the oven, and lets the warm air back into the oven to reduce the consumption of energy, meanwhile, increasing exhaust efficiency.

( Energy-saving device reduces a lot of production costs . )

Tension

In R2R production line, the base material move in different units with different temperature, at the same time, coating speed and glues are considered, so stable tension is quite important. For example, in battery coating processing, unwell tension control will cause wrinkles, and then cause explode, from this we can see that tension is the core of coating processing.

( Tension control is the most important system of R2R equipment. )

Material move in the oven via rollers, how to arrange each roller position and movement to ensure the material without scratched or slipped, due to the movement way is different from oven and other units, before the material enters the oven, precise positing is necessary and avoid from slip, when the material moves.

( The suitable and good performance R2R equipment enhance the advantage of product. )

The tension may be changed by many factors, tension correction system can help operators to control tension well, besides, the operators can correct or set the production condition fast via data record, when they change product specification, at the same time, these information can be used for optimizing coating processing to upgrade the quality, save time and cost.

Besides equipment, there are some factors to be considered, such as safety, some customers require the production line to be equipped with explosion-proof to avoid major disaster losses, on the other hand, whether the supplier provides good service and technical support is important.

Want to enhance the advantage of your product? Use the above STMART rules—Simple, Mechanical, Accuracy, Recycle & Reduce, Tension, so everyone can get a suitable and efficiency R2R production line easily.