Professionalism Is Worth the Wait: Insights into Die Design Philosophy and Value through Functional Films

2025.08.04"Indeed, the long wait was worth it. The moment I saw the film coming out of the die—uniform and crystal clear—I knew I had made the right decision. Now, I’m even more grateful that my persistence has finally been proven right." Receiving this message from the technical director of Company N was truly exhilarating for our entire team.

A well-designed film die can produce high-quality films that are uniform and crystal clear.

Diverse Applications of Functional Films Demand Uncompromising Quality Standards

Company N primarily produces various types of cast films. Cast films have a wide and diverse range of applications, and are often further processed or converted into different types of functional films. The most commonly seen functional films in the market include the following categories:

Barrier Films

Designed to block moisture, light, and other elements. Commonly made with EVOH, they are widely used in food and pharmaceutical packaging.

Conductive / Anti-Static Films

Prevent static buildup or provide conductivity. Typically based on PET or PE substrates, these films are used in electronic packaging and touch panel applications.

Optical Films

Provide functions such as anti-reflection, light diffusion, and polarization. Made mainly of PET or PMMA, they are commonly used in various display screens.

Scratch-Resistant / Abrasion-Resistant / Anti-Fouling Films

Enhance surface hardness, often achieved through hard coating treatments. These films are widely used for optical lenses and similar applications.

Self-Adhesive / Peelable Protective Films

Can be repeatedly applied and removed without leaving residue. Mainly used to protect surfaces in electronics, construction materials, and home appliances. These are typically made by combining acrylic adhesive with PE or PET films.

Heat Shrink / Heat Sealable Films

Cast films that shrink upon heating to seal products. Commonly used for bottle labels, shrink wrap, and sealing films, and are often made from PETG or PE.

Functional films have a wide range of diversified applications.

Three Core Quality Criteria That Determine the Yield of Functional Films

Regardless of the manufacturing method—whether through co-extrusion using the inherent properties of plastic materials or via coating functional layers onto film substrates—functional films must meet strict quality standards to ensure high yield in end-product applications. For this reason, cast films are typically required to fulfill the following quality criteria:

1. Thickness Uniformity

A significant proportion of functional films are used in precision electronics or optical products, where allowable thickness tolerance is generally within 1–3%. Consistent film thickness is critical to maintain performance and dimensional accuracy.

2. Surface Flatness of the Cast Film

The film surface must be free from wrinkles, orange peel texture, flow lines, air bubbles, and carbonized spots. In optical applications, even higher standards are required, such as high transparency and absence of crystal points. Not limited to optics, cast films used as substrates for printing or coating processes must also have excellent surface flatness, as it directly affects subsequent processing quality.

3. Physical and Mechanical Properties

Some cast films are subjected to stretching or orientation to meet specific functional requirements. In such cases, the consistency and reliability of the multilayer cast film structure become especially important for maintaining the desired performance.

Regardless of the specific application, all functional films must meet essential quality requirements.

When Expertise Is Misunderstood: Should You Persist or Compromise?

The technical director of Company N has many years of experience in the cast film industry and possesses extensive knowledge of various cast film manufacturing processes and applications. He understands that while the extruder is a crucial part of the front-end process in a cast film production line, the extrusion die is the true core of the system. If defects occur as the film is formed at the die, it is virtually impossible to produce high-quality film in the subsequent stages.

Several years ago, while working at another cast film manufacturing company, he encountered a particularly challenging issue. No matter how he adjusted the production parameters, the film quality remained unstable, with wrinkles and waviness frequently appearing on the film surface. The supplier of the film production line attributed the problem to the extrusion die. However, based on his experience and the actual trial results, he believed otherwise. After all, the flow channel design of the die had been optimized through simulation using the actual raw materials, and the film’s uniformity at the die exit was excellent. He insisted that the die was not the root cause and that time should be spent thoroughly inspecting each component—such as the extruder, the chill roll, and the winding mechanism. Unfortunately, the team could not reach a consensus on this approach. Eventually, he left the company and joined Company N.

Only Those Who Truly Understand Technology Can Grasp the True Value of a Die

Years later, in response to growing market demand, Company N began expanding its existing film production lines to increase the output of high-quality functional films. At that moment, the technical director was reminded of the extrusion die he had once worked with. After further communication and investigation, he came to realize that ensuring excellent quality in cast films requires the extrusion die to meet the following key considerations:

1. Geometry of the Flow Channel

The flow channel must be designed to suit the specific properties of the material, avoiding dead zones that could lead to material degradation or carbonization within the die cavity.

Additionally, the channel design plays a critical role in ensuring uniform pressure and flow velocity throughout the die. These parameters can be accurately analyzed and optimized through simulation systems.

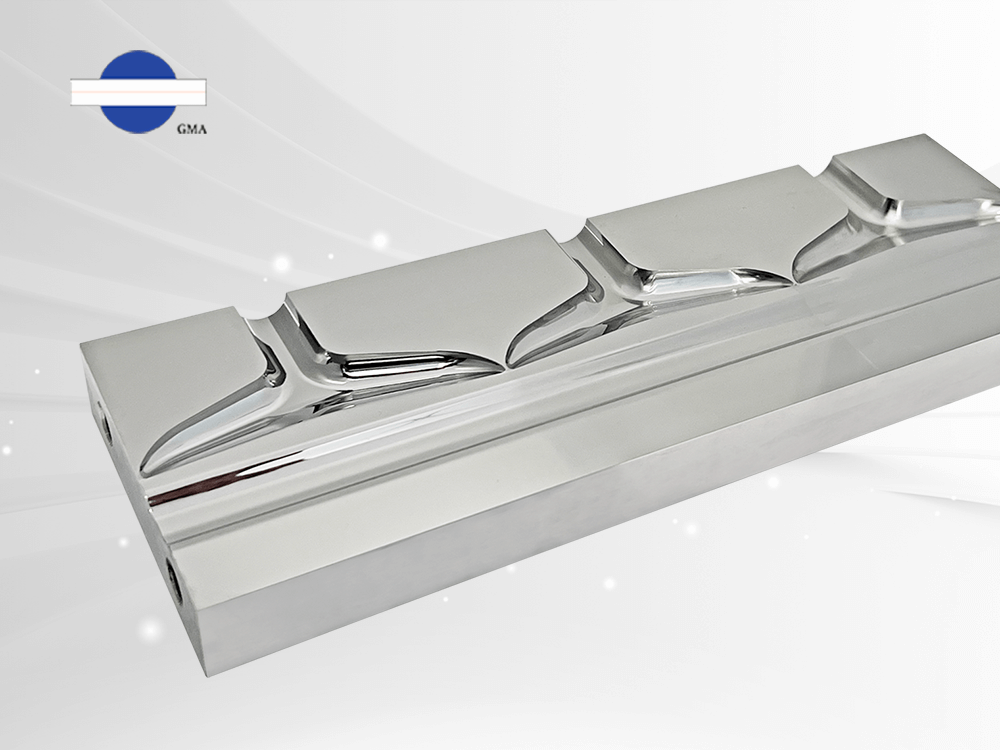

2. Die Machining

The die surface must undergo processes such as electroplating, fine grinding, and mirror polishing. The surface roughness of the flow channel should be Ra ≤ 0.02–0.04 µm to minimize flow resistance and prevent material residue buildup.

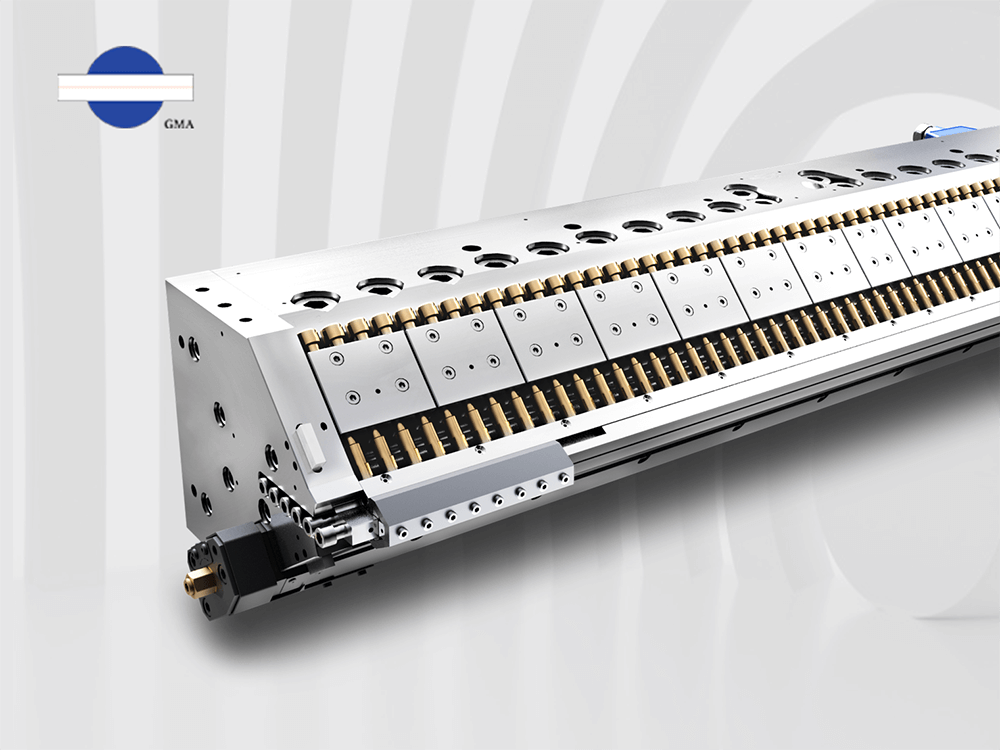

3. Temperature Control Design

Some plastic materials are relatively sensitive to temperature, making multi-zone temperature control within the die critically important. This is especially true for certain cast films that, due to process requirements, use multi-manifold dies to form multilayer structures. In such cases, each layer requires independent temperature control to accommodate different processing temperatures for each material, ensuring uniform flow and stable extrusion.

The geometry and machining of the flow channel are critical

factors in film die performance.

The geometry and machining of the flow channel are critical

factors in film die performance.

Read more: Rough? Not at all! The surface roughness is more detailed than you can imagine.

The Key to Gaining Market Advantage Lies in Risk Management—Not in Price

After several rounds of technical discussions and consideration of mass production requirements, the technical director of Company N recommended using an automated multi-manifold extrusion die. However, the lead time for producing such a die is longer than that of a conventional manual die, which made the company somewhat anxious. Drawing on his years of experience, the technical director managed to convince the rest of the team by pointing out that instead of being swayed by market pitches promising “lower prices and faster delivery,” it would be wiser to think calmly:

“A die is not like a courier package—you don’t just receive it and use it. A truly suitable die is the result of careful design validation, material selection, precision machining, and strict quality control at every step.”

While low-cost, quick-delivery products may seem to reduce upfront investment, in reality, they often lead to hidden costs down the line—through repeated machine adjustments, rework, scrap, and defective output. To stay ahead of the competition, the real concern should be risk management: the smaller those hidden costs, the lower the operational risk.

Choosing the right die is key to reducing risk and minimizing hidden costs.

Read more: From Manual Adjustments to Automated Dies: Solving Precision and Waste

"Expertise is something worth waiting for—and trusting." That's what the technical director at Company N said. In the past, his professional judgment was questioned, and the team he worked with was unwilling to wait for further validation. In the end, they failed to seize the market opportunity.

Now at Company N, he has once again proven that his expertise was right all along. Only those who truly understand the technology can fully unlock the potential of the tools they use—such as the extrusion die—and bring out their maximum performance.