Savior of research and development dept. and engineer-Slit coater lab machine

2023.05Ten years ago, GMA build multifunction production line and laboratory, for developing and improving slot die and other equipment, unexpectedly, more and more customer ask for renting our lab machine for doing some test, meanwhile, we have well coating experience engineer teams, not only help customer to do test, also provide professional suggestion, this is the most economical and practical way for developing. As people know that research and development always take much time cost and invent a lot of money , not to mention other factors, GMA provide lab machine rental service is savior to R&D dept. and engineer.

( GMA is not to provide renting lab machine service, but also provide professional suggestion. )

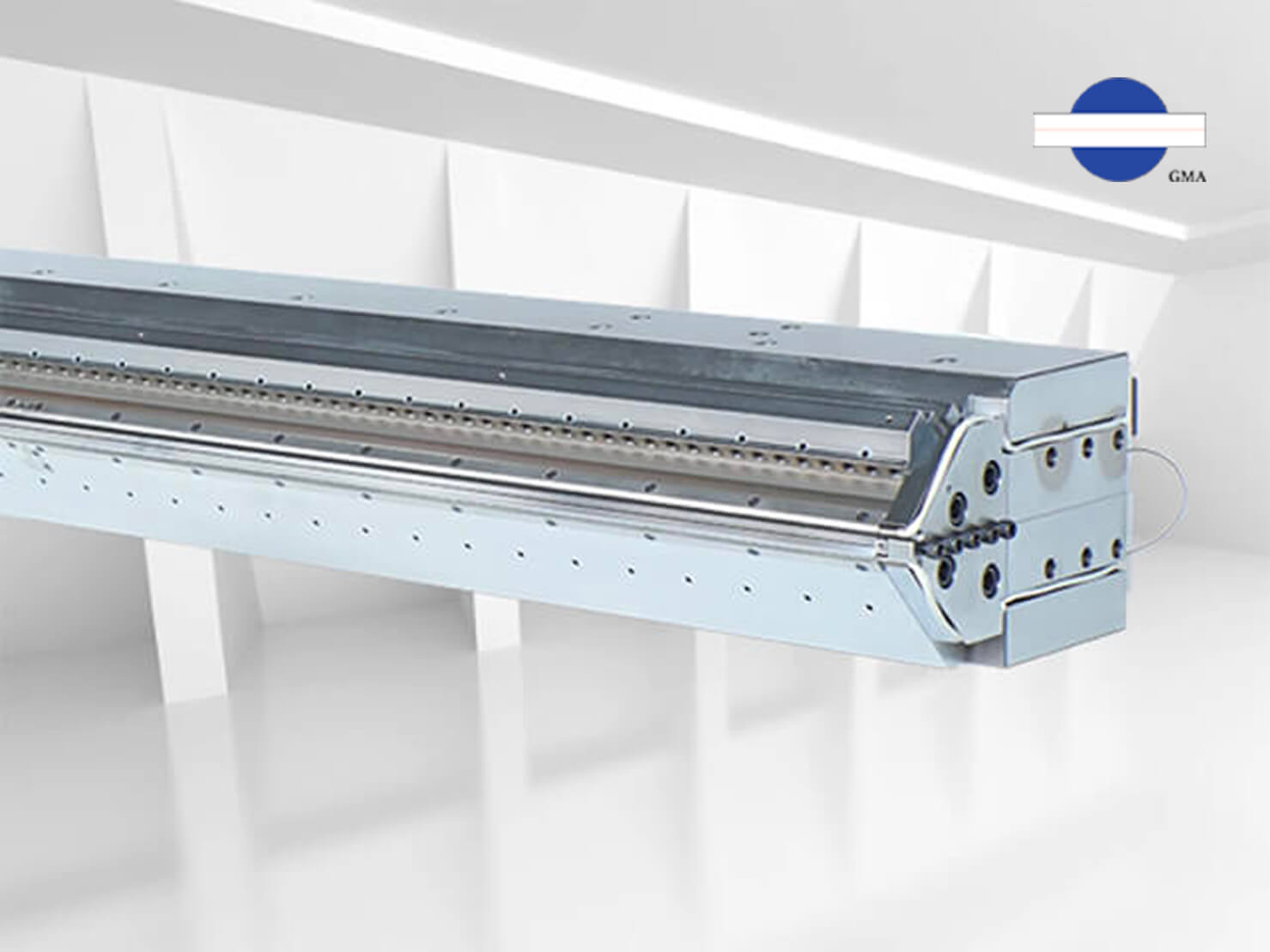

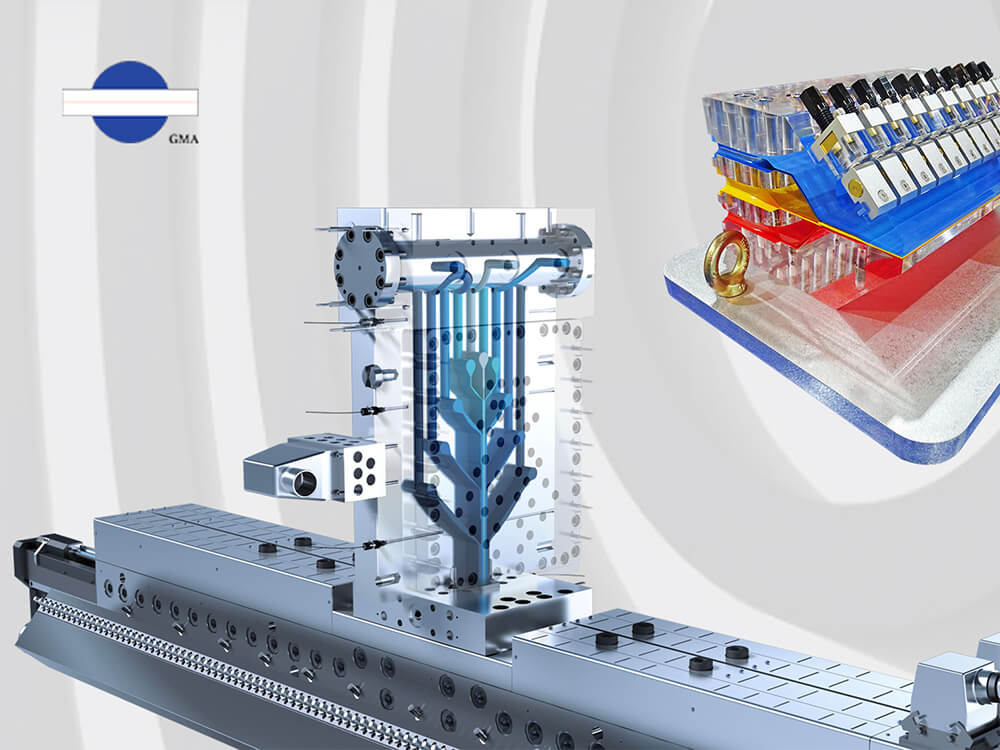

So far, we assist dozens customers , includes oversea, to develop new product, optimize current processing , evaluate existing equipment or purchase new device etc. every week, we receive test reservation from different company, from last year, besides existing multifunction lab line and small slit coater, we design and manufacture big slit coater (TAB2001) for fit new energy industry application,. TAB2001 is used for flat substrate wet coating processing, applied on flat panel display, touch panel, backlight module, transparent conductive substrate and solar energy product etc. photoresist, conductive polymer, hard coating, optical glue, copper indium gallium oxide paste can be available.

( big slit coater (TAB2001), applied for flat substrate wet coating processing. )

TAB2001 equips with the below device.

Pumping system:

Estimated coating processing with close pumping system, keeping stable pressure and quality, saving adhesive.

( closed pumping system, stable pressure, save adhesive. )

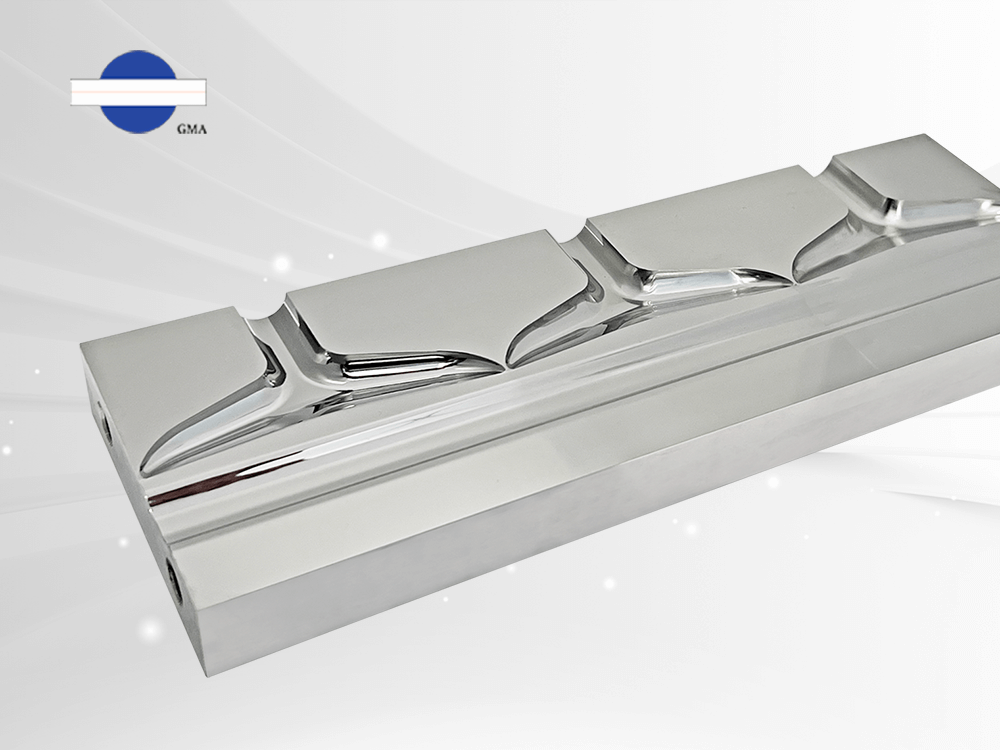

GMA slot die

Slot die made of patented stainless steel SUS630 serial, extremely precision processing, straightness and lip flatness within 2.5um, roughness of landing area is under Ra0.03um, with self-cleaning system for longer and more stable production , extend slot die working time, reduce die maintainance time.

( GMA slot die with self-cleaning system and horizontal correction system. )

Die horizontal correction system avoid die position shift due to disassemble of cleaning, ensure the coating quality, position accurately correction is within 2um.

Vacuum platform and air flotation system:

Vacuum platform made of marble with adsorption positing, various size substrate are available, with air flotation shaft controlled by linear motor to ensure the stable movement, avoid pause coating mark of slot die moving, it is good to high standard flat coating processing.

Loading and unloading substrate via thimble, controlled by servo motor, it is adjustable to fit the loading or unloading speed.

Electronic and operation system

Recorded production condition and parameter automatically, can work with automatic production, meanwhile, operation interface is easy to operate, can be operated via mobile phone or pad.

( easy to operate, can be operated via mobile phone. )

If customer wants to purchase TAB2001 type lab machine, we offer customized service for control system or add other device, such as UV curing, oven, vacuum dry etc.

Research and development always take a lot time and cost, in fierce competition market, who can convert innovation into product to create business first, who is the winner, on developing long way, GMA is always stay with you, to be your best partner and strong backing.