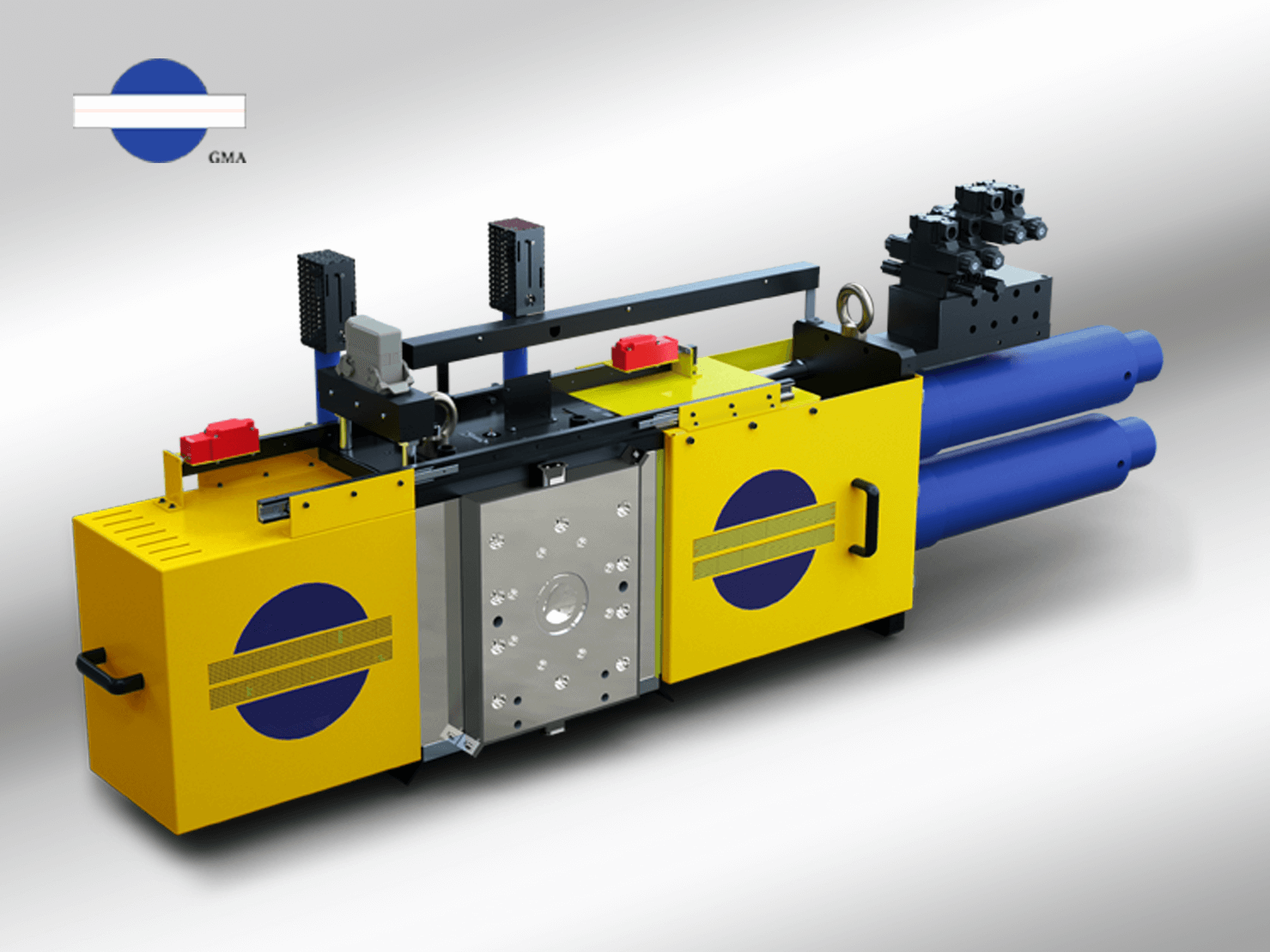

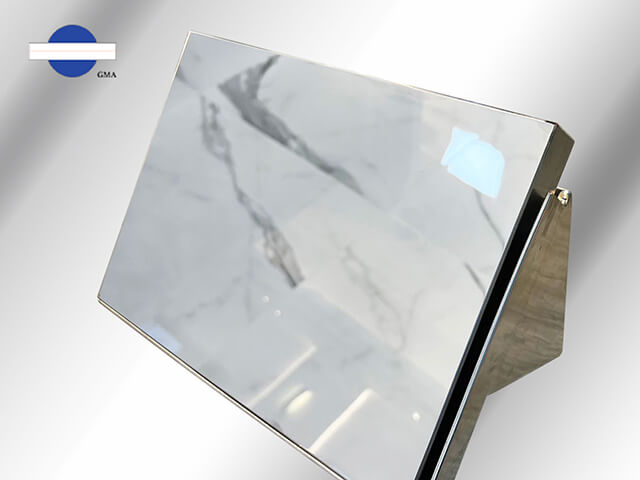

SCREEN CHANGER

NON-STOP SLIDE PLATE

SUITABLE APPLICABLE WITH

General Polymers

Feature

- The flow channel is with smooth surface via precision processing, avoid from material stay in channel.

- Movable break plates, enhancing filtration efficiency and easy removal for cleaning.

- With an accumulator cylinder, replacing mesh without stopping the production line, reducing production losses.

- Suitable for most plastic materials, excluding halogen-containing ones like PVC and PVDF.

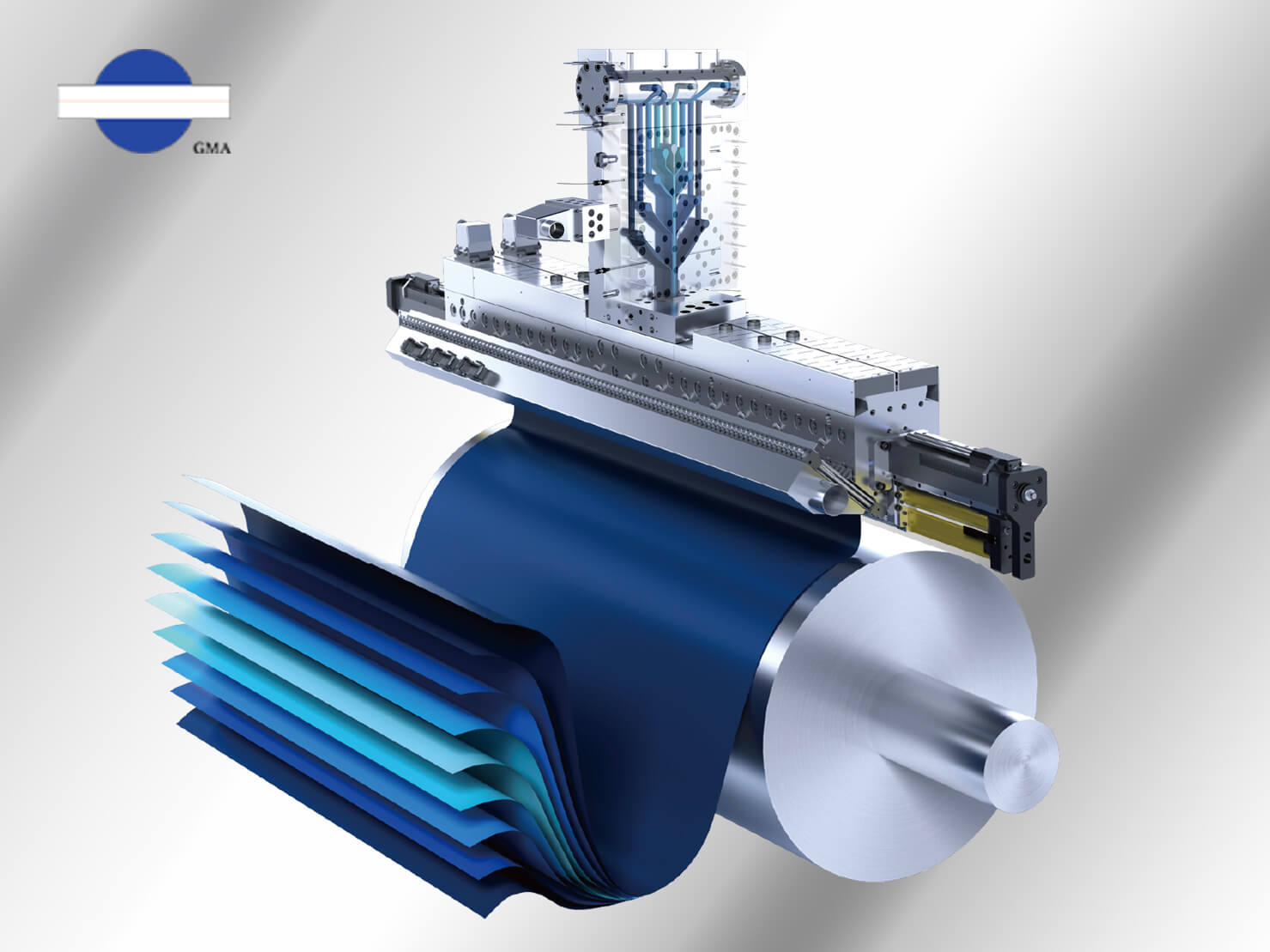

- Applications: optical products, films, lamination, and sheet extrusion lines etc.

Catalog Download

Add to

inquiry cart

| SPECIFICATIONS | |||||||

| Model | Capacity(kg/hr) | Fiiter dia. | Filter area(cm²) | Heaters | Heating zone | Recommend mesh dia.(mm) | Total thickness of mesh(mm) |

| No 35 | 25~45 | Ø 48 mm | 14 | 10 | 1~3 | Ø 44 mm | 3 |

| No 55 | 60~135 | Ø 72 mm | 35 | 10 | 1~3 | Ø 68 mm | 4 |

| No 65 | 70~165 | Ø 88 mm | 48 | 10 | 1~3 | Ø 82 mm | 4 |

| No 75 | 80~180 | Ø 92 mm | 75.5 | 10 | 1~3 | Ø 88 mm | 4 |

| No 90 | 120~280 | Ø 113 mm | 91.5 | 10 | 1~3 | Ø 107 mm | 4 |

| No 100 | 140~330 | Ø 127 mm | 113 | 10 | 1~3 | Ø 119 mm | 4 |

| No 120 | 200~450 | Ø 150 mm | 163 | 10 | 1~3 | Ø 144 mm | 4 |

| No 150 | 300~850 | Ø 200 mm | 254 | 12 | 1~3 | Ø 196 mm | 4 |

| No 200 | 500~1350 | Ø 248 mm | 452 | 12 | 1~3 | Ø 240 mm | 6 |

Use Field

INDUSTRIAL CONSTRUCTION MATERIAL

PHOTOELECTRIC NERGY SAVING

STATIONERY COMMODITY