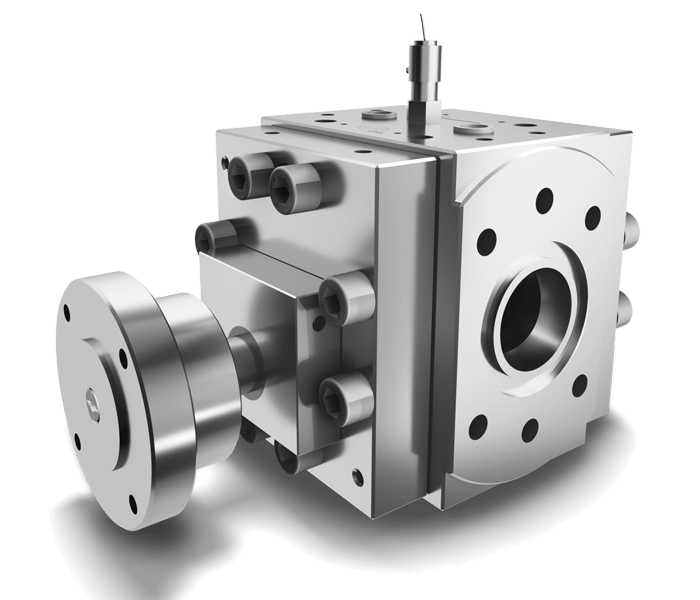

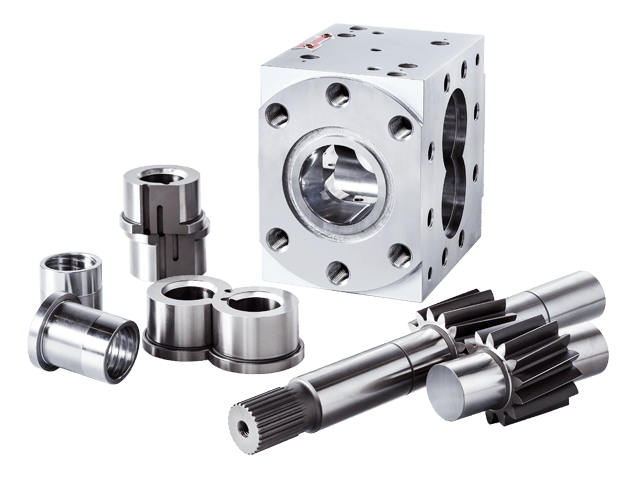

GEAR PUMPS

POLYMER RESIN

Feature

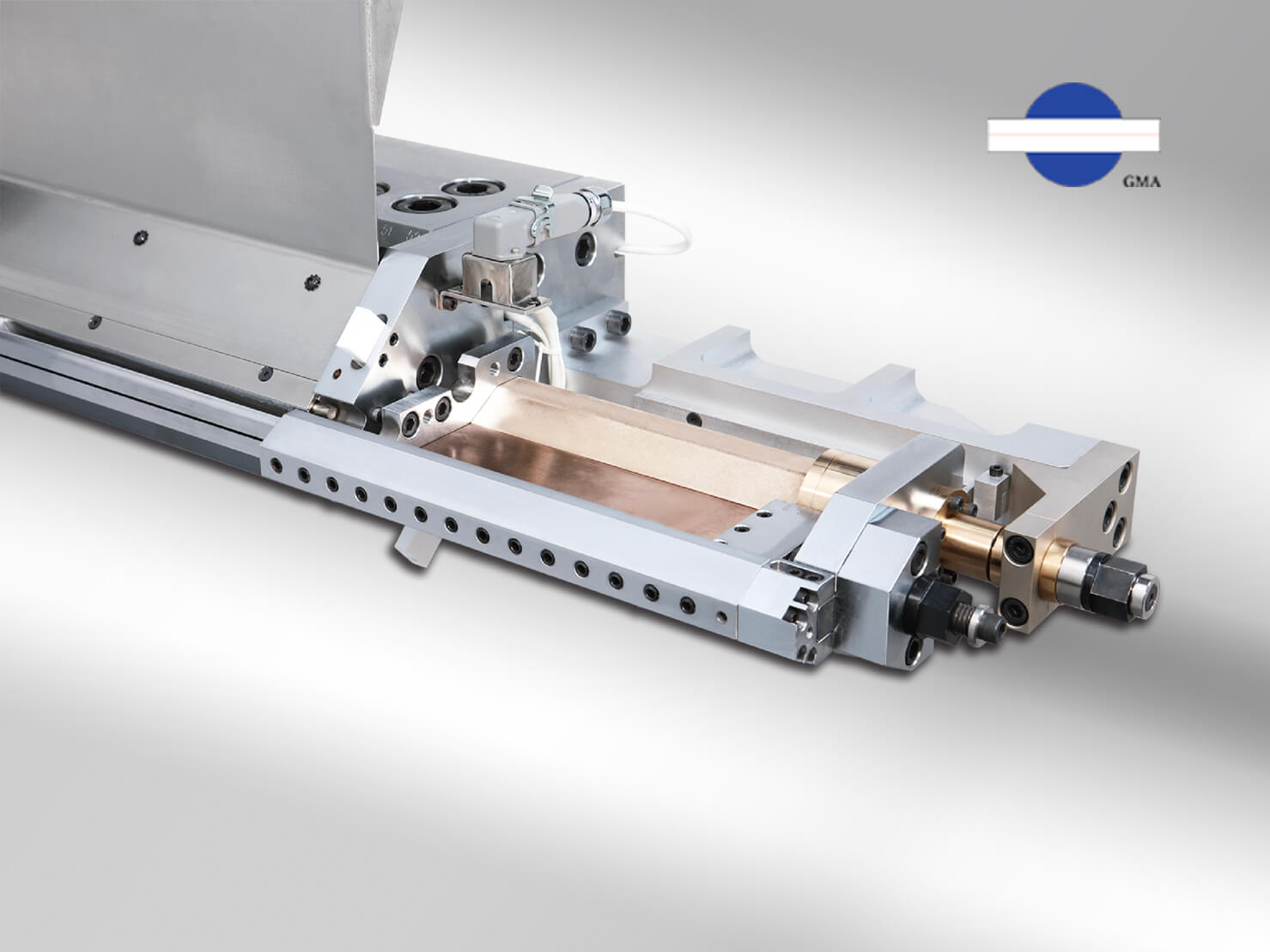

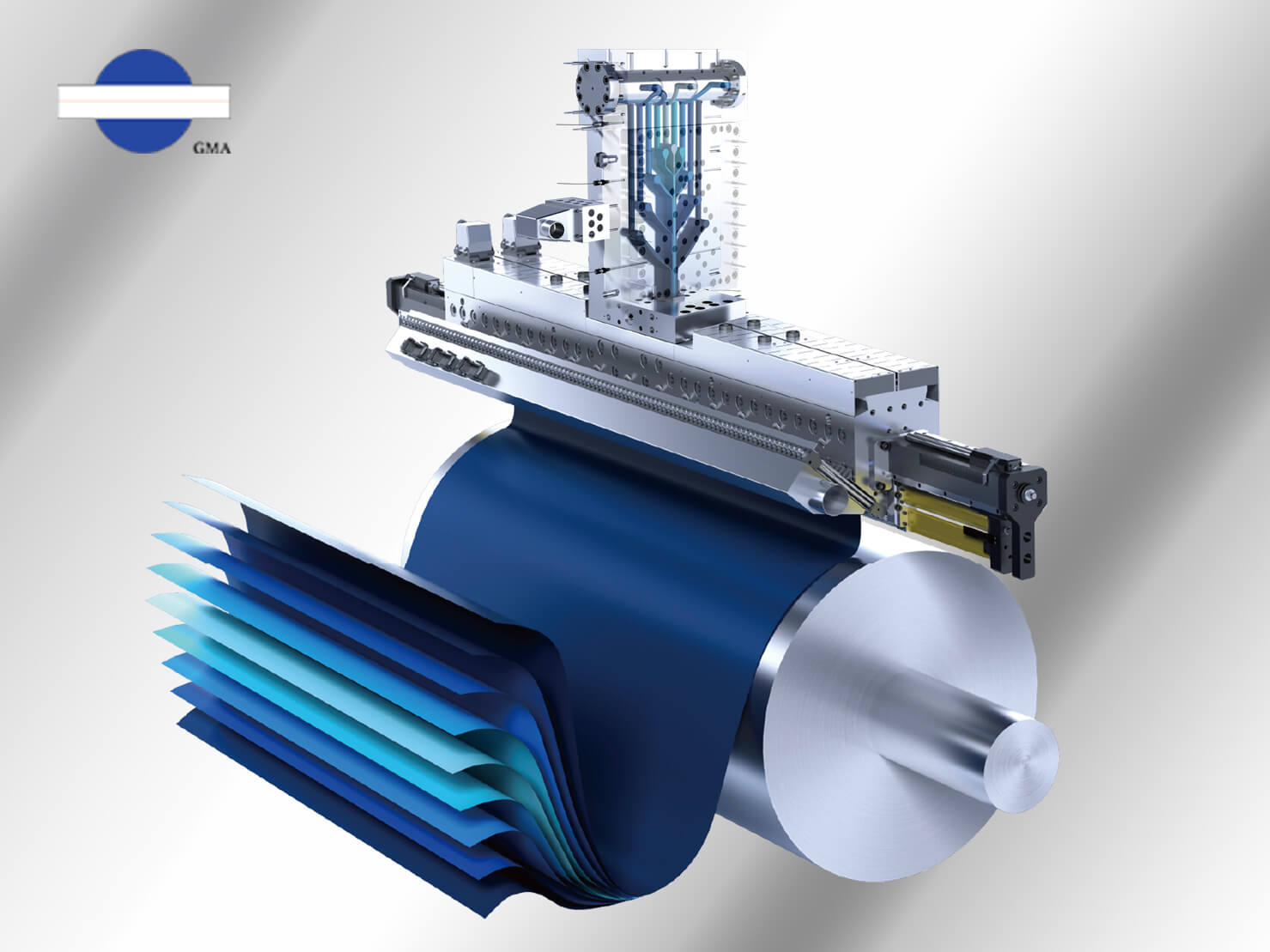

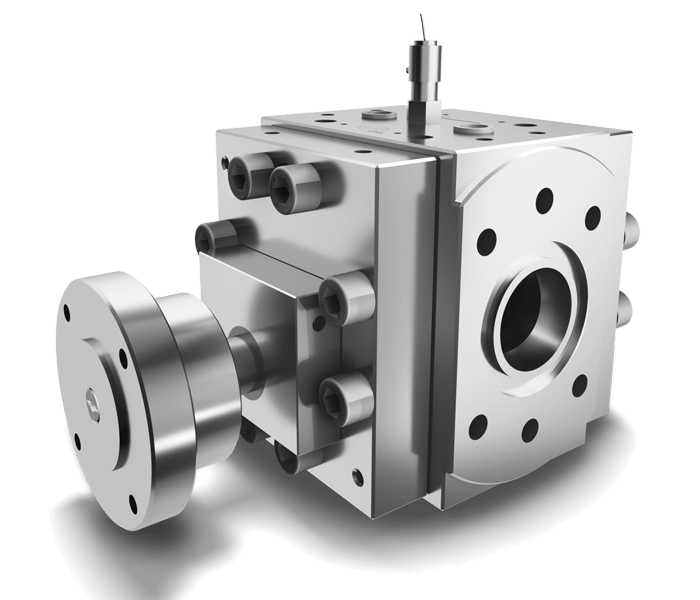

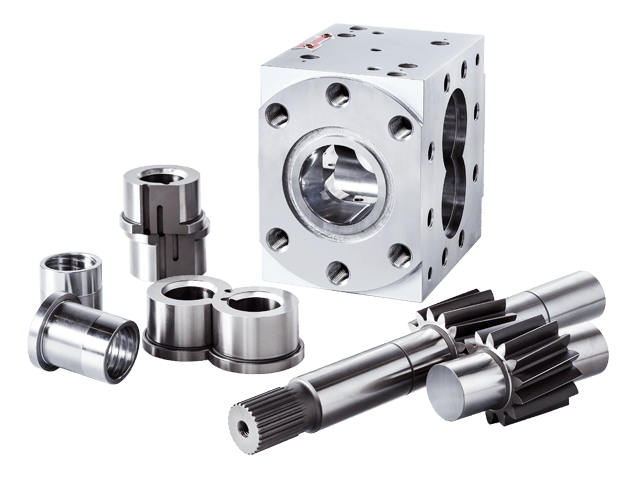

- Precision gear pump, ensure volume rate is over 98%, low reflow rate, reduce running mechanical thermal energy.

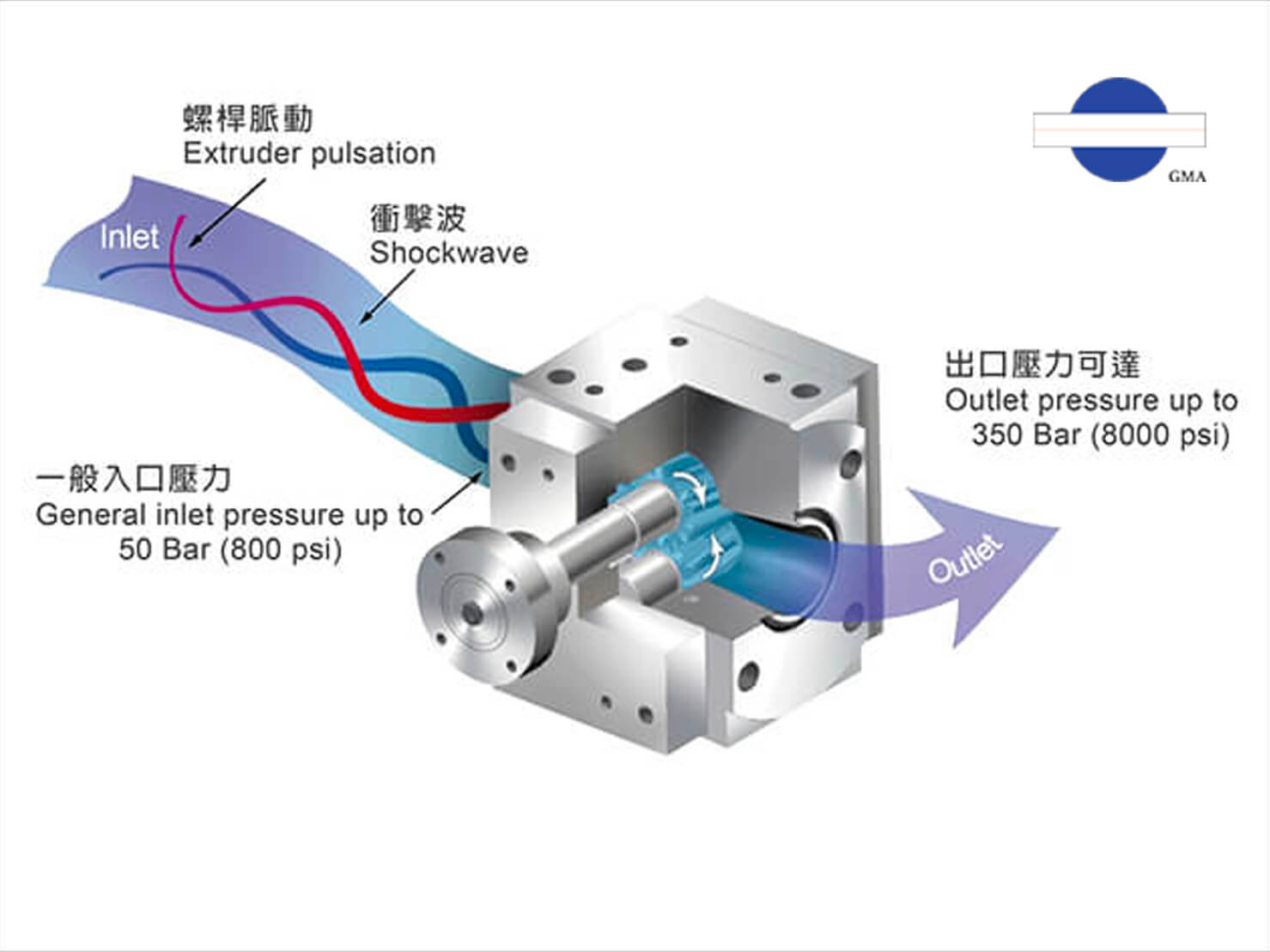

- Reducing pulse from extruder, keeping stable output, avoiding from material loss, and extruder energy consumption.

- The pressure between inlet and outlet is 250 bar

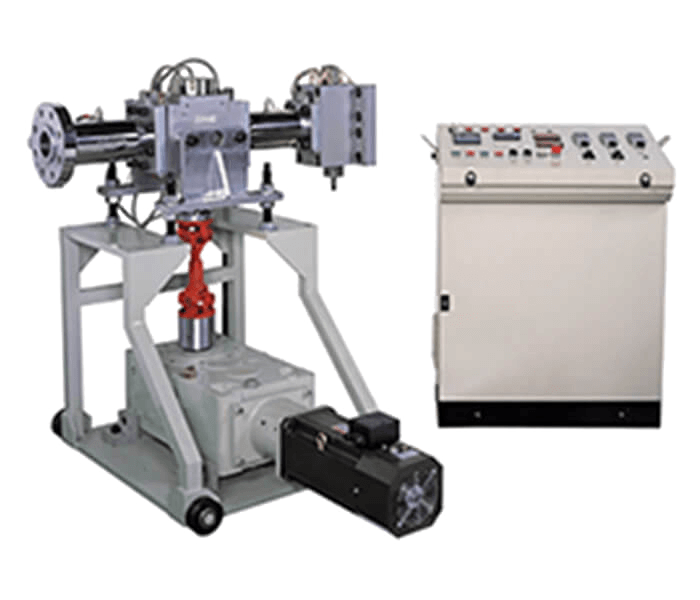

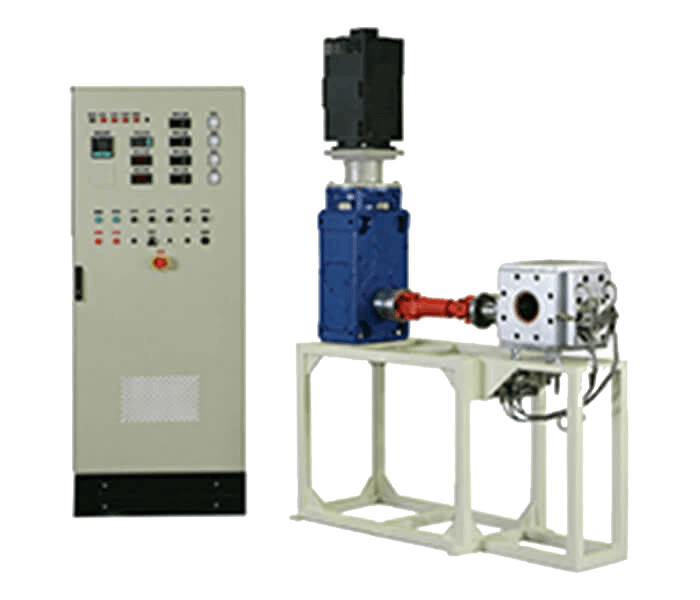

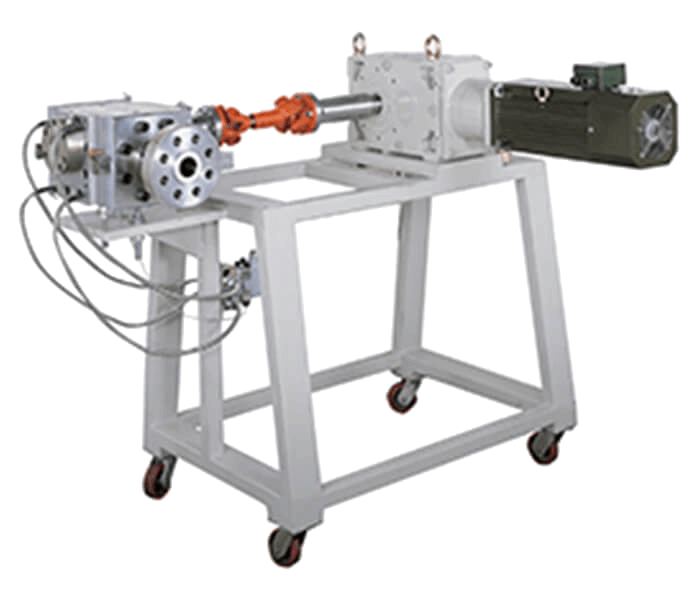

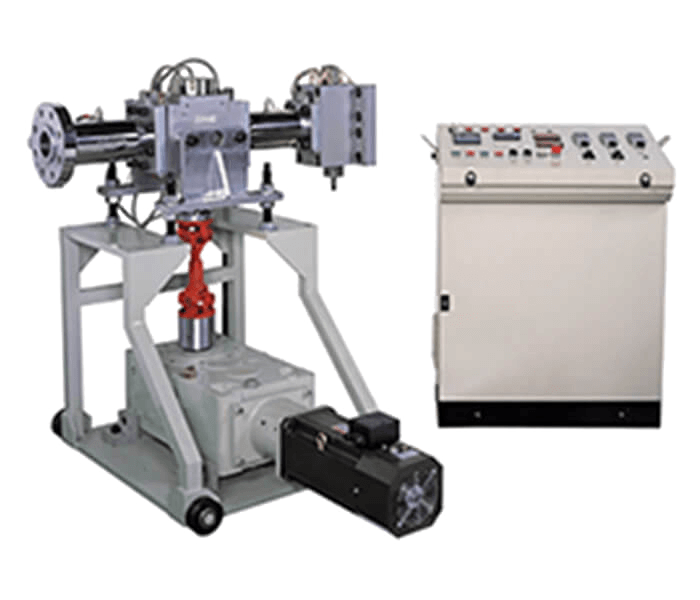

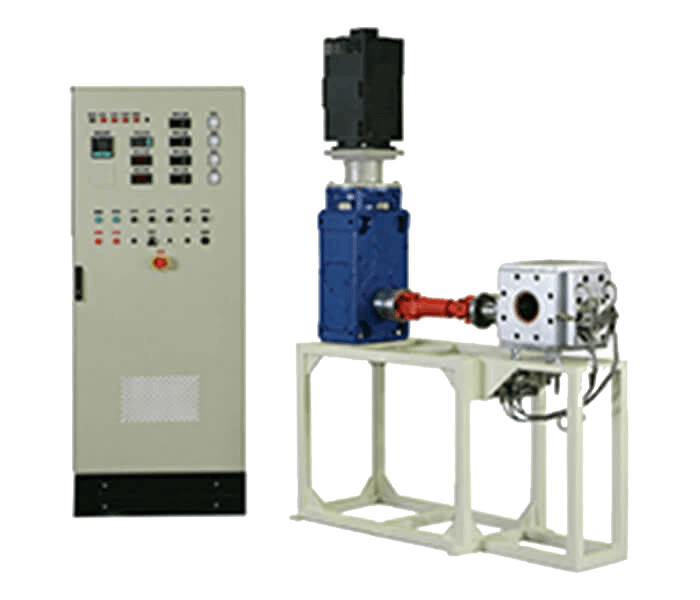

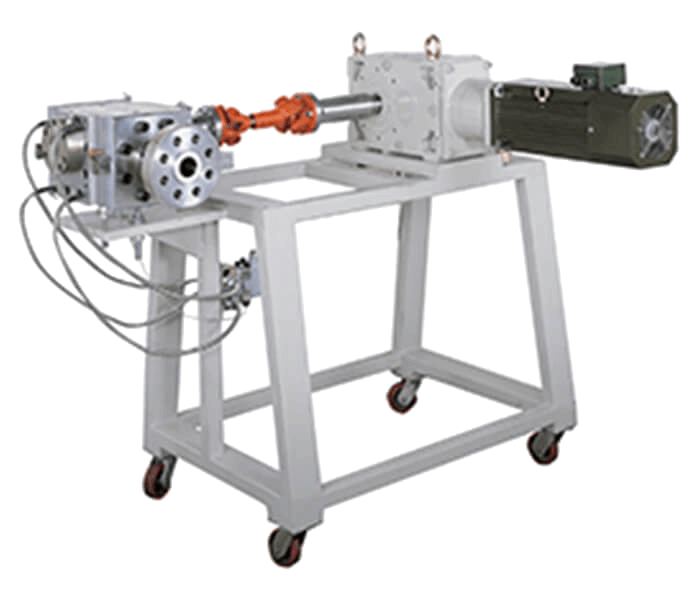

- Optional frame, drive and control system.

- Suitable for most plastic materials, excluding halogen-containing ones like PVC and PVDF.

- Optional oil heating model, if customer require.

Catalog Download

Add to

inquiry cart

| SPECIFICATIONS | |||||

| Application | LD - PE, LLD - PE | PC | PMMA | HI - PS | |

| Viscosity ( Pas at 10 / sec. ) | 1500 - 4000 | 1000 - 2500 | 2000 - 4000 | 2000 - 4000 | |

| Density at melt ( g / cm3 ) | 0.73 | 1.08 | 1.09 | 0.93 | |

| ( cc / rev. ) | rpm kg / hr | rpm kg / hr | rpm kg / hr | rpm kg / hr | |

| JYP - 20 | 2.1 | 155/13.5 | 78/10.2 | 116/15.2 | 124/13.8 |

| JYP - 22 | 4.7 | 155/30.5 | 78/23 | 116/34 | 124/31 |

| JYP - 28 | 10.2 | 148/63 | 70/44 | 114/72 | 120/65 |

| JYP - 36 | 25.6 | 132/140 | 62/100 | 104/165 | 110/150 |

| JYP - 45 | 46.3 | 125/240 | 62/180 | 94/270 | 96/235 |

| JYP - 56 | 92.6 | 107/410 | 62/360 | 85/490 | 92/450 |

| JYP - 70 | 176 | 102/750 | 56/610 | 76/830 | 82/760 |

| JYP - 90 | 371 | 87/1350 | 52/1200 | 66/1520 | 72/1410 |

| JYP - 110 | 716 | 77/2300 | 42/1880 | 57/2520 | 62/2360 |

| Application | ABS | GP-PS | PP | A - PET | |

| Viscosity ( Pas at 10 / sec. ) | 3000 - 5000 | 1500 - 2500 | 1000 - 2000 | 1300 - 2000 | |

| Density at melt ( g / cm3 ) | 0.96 | 0.93 | 0.73 | 1.17 | |

| ( cc / rev. ) | rpm kg / hr | rpm kg / hr | rpm kg / hr | rpm kg / hr | |

| JYP - 20 | 2.1 | 109/12.5 | 157/17.5 | 156/13.6 | 158/22.3 |

| JYP - 22 | 4.7 | 109/28 | 157/39 | 156/30.5 | 158/50 |

| JYP - 28 | 10.2 | 107/60 | 142/77 | 151/64 | 145/100 |

| JYP - 36 | 25.6 | 100/140 | 136/185 | 141/150 | 139/240 |

| JYP - 45 | 46.3 | 86/216 | 122/300 | 125/240 | 128/400 |

| JYP - 56 | 92.6 | 83/420 | 111/545 | 117/450 | 118/735 |

| JYP - 70 | 176 | 77/740 | 102/950 | 106/775 | 107/1265 |

| JYP - 90 | 371 | 67/1350 | 85/1680 | 96/1480 | 96/2415 |

| JYP - 110 | 716 | 58/2260 | 67/2540 | 86/2550 | 86/4140 |