The best Auxiliary equipment of extrusion production line—Gear pump

2022.08Are you suffering of uneven thickness sheet, let GMA team help you !

Every day, we received some inquiries from phone, website or mails, one kind of inquiries is for asking professional assistance. AAA company told us their PP sheet with uneven thickness problem, it caused the poor quality of processing and forming, meanwhile, it made their business getting worse, they tried to adjust the extrusion die , but it was not help, so they contacted us for asking help.

Find out the real problem, and solve it!

When GMA team, sales person and service engineer, went to customer's site, they saw the polymer come from the extrusion die to be uneven obviously, the engineer tried to adjust the extrusion die for checking whether the die is workable normally or not, it seemed the problem was not caused by extrusion die. the engineer check all data showed on operation panel, there was only pressure sensor before screen changer, it was no reference, because the pressure value is changed, due to the inside mesh, no pressure sensor was installation after filter, the engineer checked electric current of extruder motor, according to our experience, for producing PP sheet, 500 kg for per, the current range should be in around positive or negative 7%, compared with setting value, but currently, the current data was over 10%, it means that the output was not stable before entering into the extrusion die, this is the reason why sheet thickness is uneven.

After further discussion with customer, we knew customer used some recycle PP flake for saving cost. Recycle polymer causes bridging or skid in the extruder easily, it would cause pulse from extruder, higher pulse cause higher pressure between extruder and extrusion die, if the higher pressure can’t be controlled well, the output will be unstable, since extrusion die receive unstable polymer, it is difficult to make even distribution, not to mention even thickness sheet.

It looks simple, but with big contribution to extrusion line.

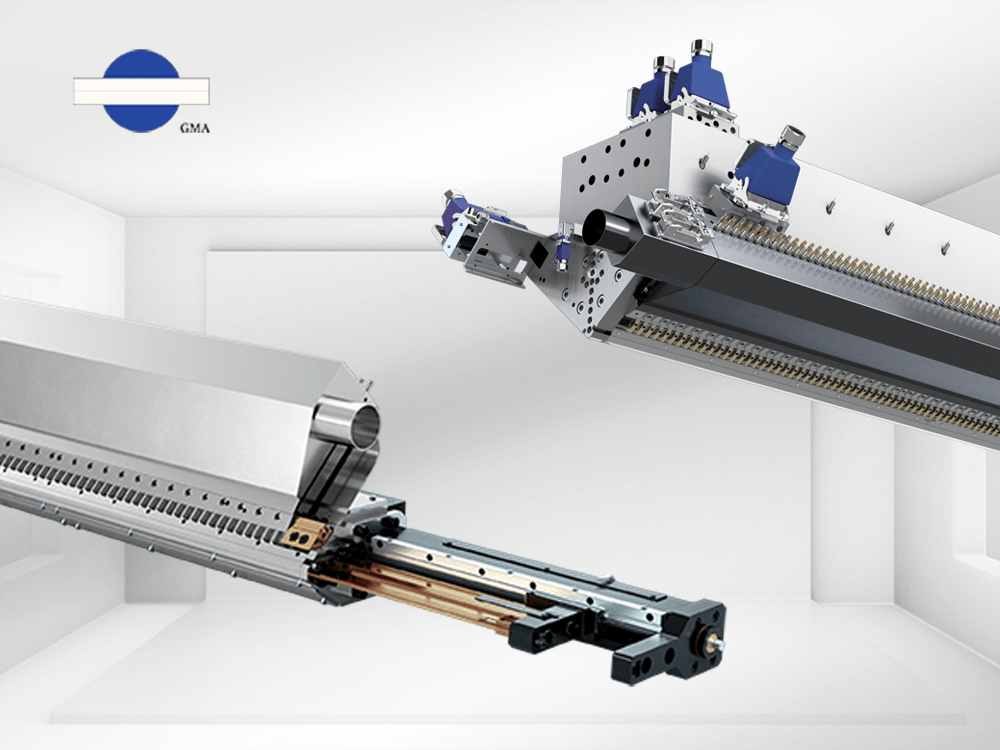

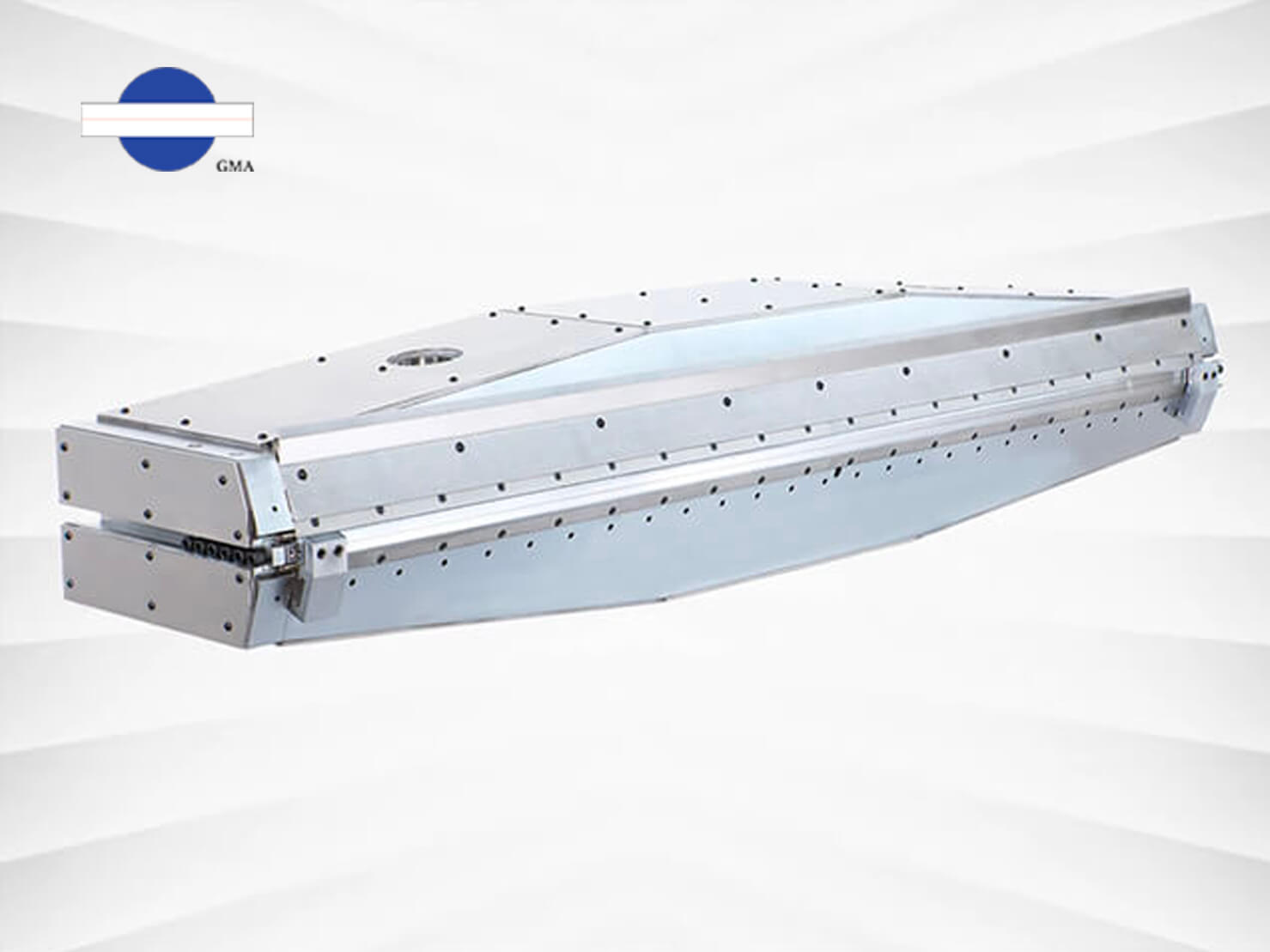

For reducing extruder pulse impaction, we suggest customer to install gear pump on production line. Gear pump is not the main equipment to extrusion line, for saving cost, some machinery companies are used to without gear pump, but actually gear pump has very helpful contribution of extrusion line. recently decade, more and more modified green polymer, recycle plastic, multi-layers structure and high capacity are required, for meeting the requirement, many companies focus on improving their equipment, includes GMA, we are not to focus on extrusion die, also improving gear pump design and processing, GMA gear pump can be used for most plastic polymer, includes recycle, elastomer polymer for assisting stable output.

For eliminating extruder pulse impaction, we suggest customer to install gear pump on production line. Gear pump is not the main equipment to extrusion line, for saving cost, some machinery companies are used to without gear pump, but actually gear pump has very helpful contribution of extrusion line. recently decade, more and more modified green polymer, recycle plastic, multi-layers structure and high capacity are required, for meeting the requirement, many companies focus on improving their equipment, includes GMA, we are not only to focus on extrusion die, but also improving gear pump design and processing, GMA gear pump can be used for most plastic polymer, includes recycle, elastomer polymer for assisting stable output.

AAA company accepted our suggestion to install gear pump with control system on their production line, during installation time, they also sent their die to GMA for maintenance, after one week, when the gear pump running on their line, we saw customer smile, that is definitely the best praise to GMA team.